September 15, 2015

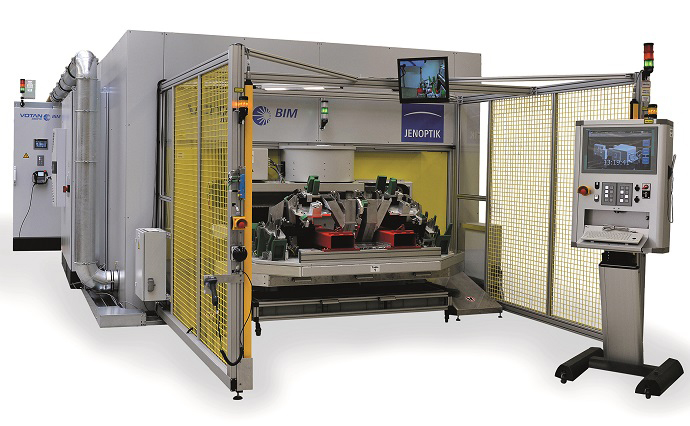

With its wide range of products, Jenoptik's Lasers & Material Processing division offers solutions for cutting, welding and perforating of plastics. At the Fakuma trade fair in Hall A2, booth 2317, Jenoptik will for example present the robot arm that is the heart of the JENOPTIK-VOTAN® BIM laser machine for precise 3D laser cutting. The second highlight will be a welding demonstration system of the JENOPTIK-VOTAN® W machine that allows fast and contactless plastic welding.

Precise 3D Plastics Cutting with JENOPTIK-VOTAN® BIM

Laser cutting of plastics allows a highly efficient processing of complex 3D parts. The non-contact process preserves the material and minimizes costs which would incur because of set-up time or tool wear. In addition, plastics laser cutting also ensures high-quality edges. Jenoptik solves typical problems, such as formation of deposits by utilizing of Jenoptik-manufactured exhaust cleaning systems.

The system concept of the JENOPTIK-VOTAN® BIM series is based on a beam guide inside the robot. This allows using CO2 lasers with a power of up to 5 kW without having to use a complex external beam guide that often causes collisions. At the same time, the equidistant beam path prevents the laser beam from pumping, ensuring a stable beam quality.

This approach makes the Jenoptik system an optimized tool for cutting of all 3D plastic parts of a vehicle, for example inner doors or bumpers. Due to its high flexibility, JENOPTIK-VOTAN® BIM is the ideal, virtually wear-free tool for processing of a variety of working parts even if you have only one laser machine, because you don't need the special cutting dies as during the conventional processing.

Fast and Reliable Plastics Welding with JENOPTIK-VOTAN® W

In order to expand the applications of the laser beam welding, Jenoptik has developed a welding technique with free radiating diode lasers. Diode lasers have been used as pump sources in disk lasers for years and are used by Jenoptik as direct emitters, too. They provide the following characteristics:

- very high efficiency, since no loss through fiber coupling,

- high power output of up to 120 W per module,

- high reliability and long lifetime of more than 20,000 operating hours,

- standard wavelengths of 808 to 980 nm,

- flexible scaling with favorable price-performance ratio,

- compact and robust design.

Opposed to welding with focused laser sources, the free radiating diode lasers work similar to a light curtain; that means, they have a collimated beam path with focus depths of up to 200 mm. When the laser beams hit the absorbing plastics, the laser energy light is converted into heat energy along the irradiated line. This special characteristic of the free emitters offers the possibility to vary the working distance so that 3D parts can we welded even without using complex optical systems or high-precision handling systems. Another important advantage of welding with free radiating diode lasers lies in its easy scalability, allowing high productivity while keeping the operating costs relatively low.

For welding large plastic parts such as airbag chute channels in instrument panels or door trim panels of a vehicle, Jenoptik combines several diode lasers to one diode laser line. This allows effective and firm welding of large parts in one run.

Watch a live demonstration of 3D laser cutting and welding at Jenoptik’s booth 2317 in Hall A2 at the Fakuma trade show in Friedrichshafen, from October 13 to 17.