February 2, 2018

At present, two methods are primarily used for aligning doublets: manual alignment and automated active alignment. Since switching between these methods is a big step both financially and proce-durally, many users of the traditional manual method are wary about making the change.

In traditional doublet cementing processes, the measurement is done on a lens rotation device, for example. With this method, the edge of the lower lens is joined to a V-edge and the lens is rotated using a friction wheel. The upper lens can be aligned manually by tapping it into position or by us-ing a manually-operated air manipulator. “However, these conventional alignment methods often reach their limits nowadays,” explains product developer Tobias Schenk. “These limitations affect both the efficiency, which can hardly be increased in the manual processes since they are already fully developed, as well as the quality assessment of the final alignment result. Since the alignment is frequently assessed on a purely visual basis, a certificate of completion usually cannot be creat-ed.”

To address this problem and close the gap between conventional and automated active alignment methods, Schenk has developed a new alignment module: the LensAlign 2D Air for devices in the OptiCentric® series. This is a cost-effective entry-level solution in the range of TRIOPTICS LensAlign modules, bridging the gap between traditional manual alignment techniques and auto-mated active alignment.

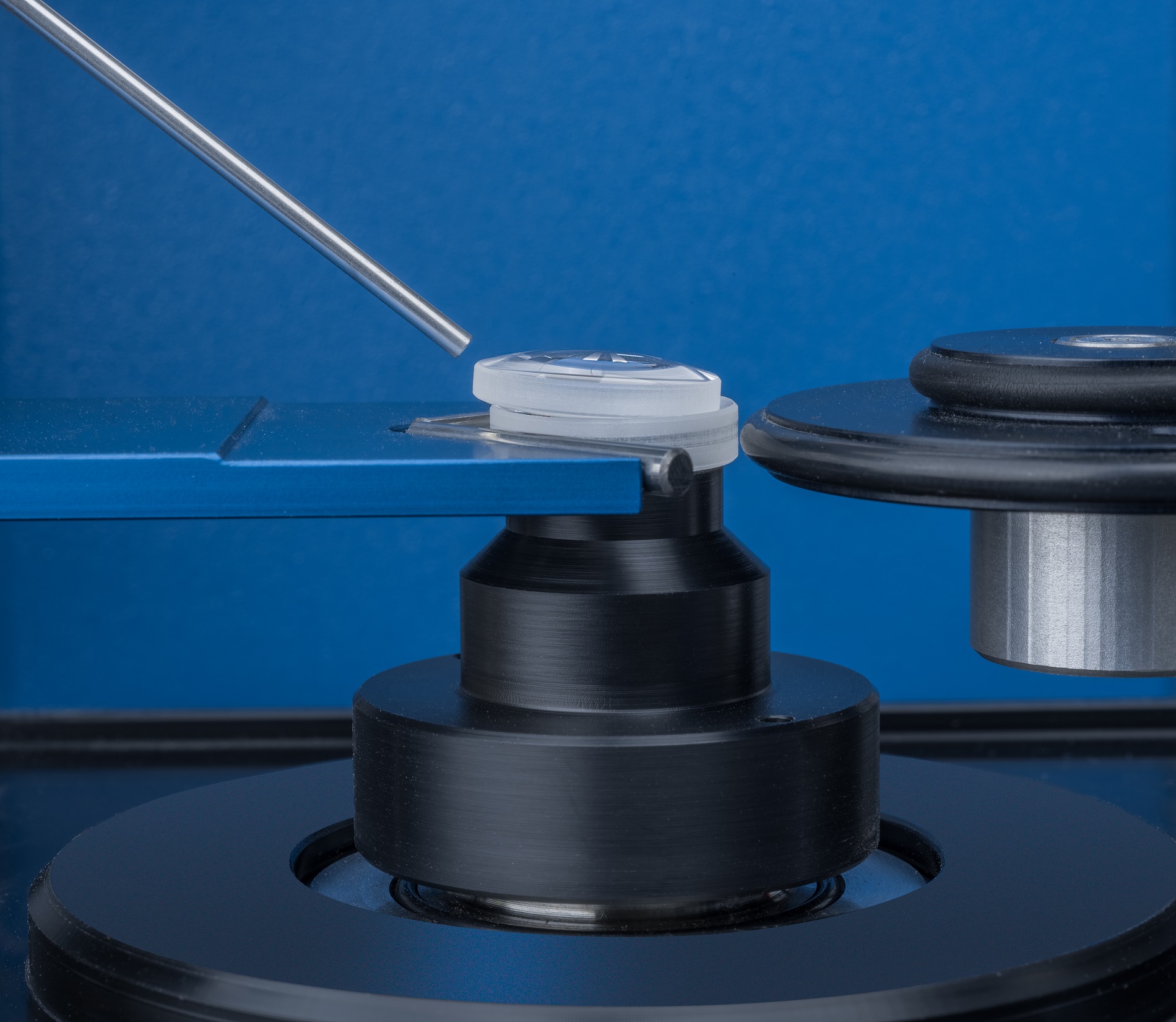

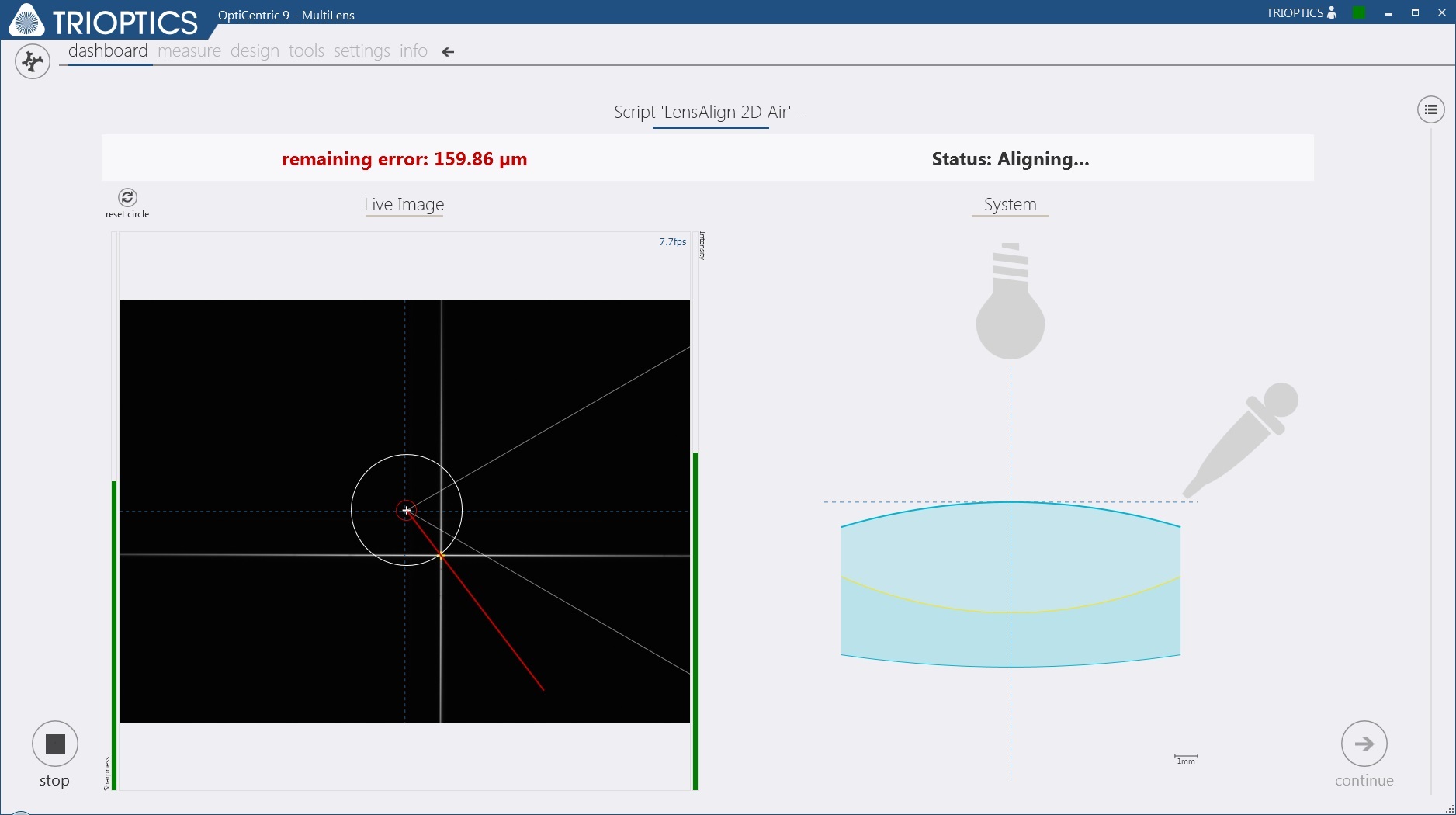

“The basic structure of the centering system can usual-ly remain intact, with no modifications needed. We rec-ommend a combination of the OptiCentric® 100, the lens rotation device and our new OptiCentric® 9 soft-ware,” Schenk clarifies. “LensAlign 2D Air now en-hances this system by adding an automatically con-trolled air manipulator. During the rotation, the upper lens is moved into the tolerance range of the centration by software-controlled air pulses, instead of manually moved by the operator, as was previously the case.” A tolerance range can be specified for this purpose, and is then shown in the software as a target circle. The current remaining error is displayed as an alignment vector. As long as it appears red, and is thus above the tolerance value, the software automatically triggers further air pulses.

The duration and time of the air pulses are controlled by the software, based on the decentration. To achieve an optimal alignment result, the strength of the air pulses can be adjusted according to the lens type and size. The operator-independent process thus ensures consistent alignment quali-ty and improved process safety and reliability. The contactless alignment by the air manipulator protects the material and preserves the lens quality.

Lens alignment using an automated air manipulator: Air pulses move and align the lens, without requiring any operator intervention. The process can be monitored via the software until the lens reaches a centering point below the tolerance value, visualized by the red inner circle. The red alignment vector then turns green.

Depending on availability, the cement can also be cured by UV lamps in a software-controlled pro-cess. “For the first time, this method enables automated and operator-independent lens alignment with the lens edge of the lower lens as a reference,” Schenk points out. In a last process step, the final result is quantified.