April 19, 2018

Hamamatsu Photonics has developed compact laser diode modules that emit a uniform highintensity beam capable of pumping high-power industrial pulsed solid-state lasers. These new laser diode modules will vastly improve production efficiency during laser machining and processing

Hamamatsu Photonics has developed new laser diode (LD) modules that are extremely compact yet emit a uniform high-intensity beam of light. These new LD modules consist of stacks of LD bars that we designed and manufacture in-house and offer the world’s highest level output power. These new LD modules now make it possible to pump 10-joule class and 100-joule-class high-power industrial solid-state lasers and so will help improve production efficiency during laser processing such as in laser peening for hardening the surface of metallic materials used for transport and shipping equipment.

These new LD modules were developed in part by assistance from the “Development of advanced laser processing with intelligence based on high-brightness and high-efficiency next-generation laser technologies” project supported by NEDO (New Energy and Industrial Technology Development Organization), a national research and development agency in Japan. From here onward, we will be developing these LD module products even further to meet more wide-ranging market needs. These newly developed LD modules will be on display at NEDO’s booth (G-26) at the Optics & Photonics International Exhibition OPIE ’18 to be held in Pacifico Yokohama (Nishi-ku, Yokohama, Japan) for 3 days from April 25 (Wed) to 27 (Fri).

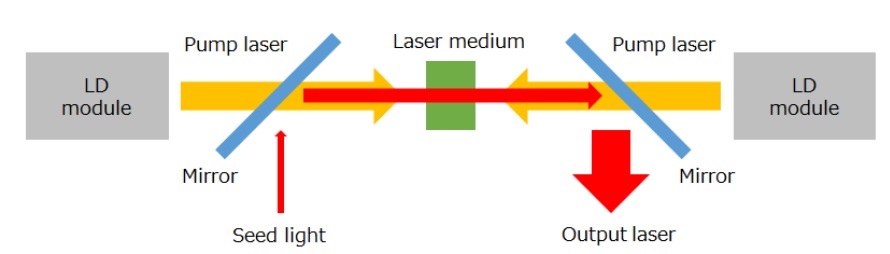

Pumping: Process in which atoms and molecules are excited to a higher energy level by absorbing light. Solid-state pulsed lasers emit laser light with energy amplified by irradiating low-power seed light onto the laser medium that is pumped or excited with LD modules.

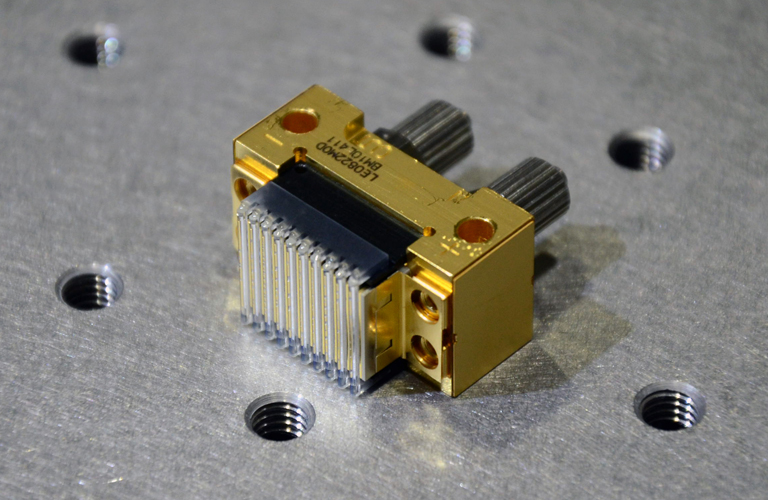

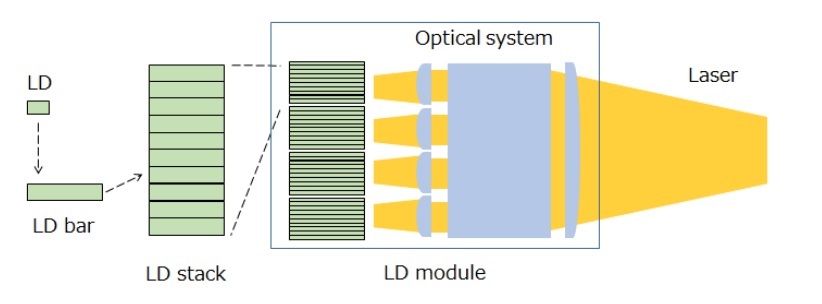

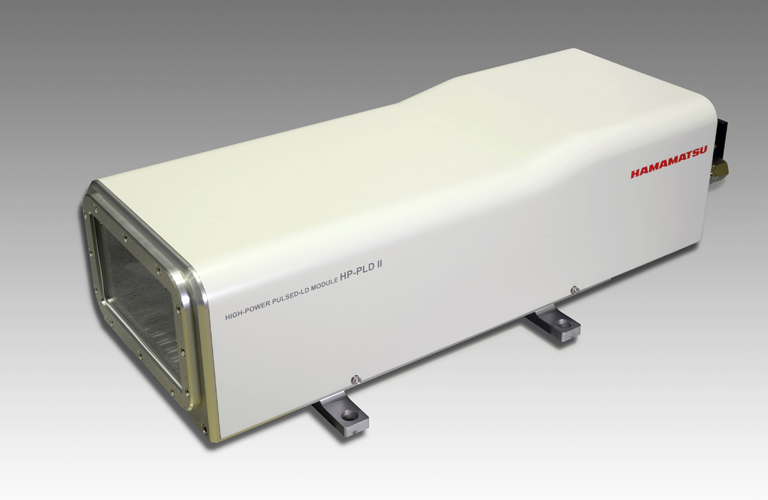

Schematic view of LD module

Key points of this newly developed product

◇Succeeded in developing compact LD modules that uniformly emit high-power laser light.

・Enhanced the output power of LD stacks up to the world’s highest level by using LD bars with an output power 4 times higher than ever before by optimizing the design and applying our advanced crystal growth technology.

・Established our unique technology for LD stack assembly that allows compact and efficient cooling. This tech also shrunk the new LD module volume to 1/5th that of other LD modules. ・Our unique optics design technology ensures uniform laser emission over the irradiated target surface.

◇Developing these new LD modules makes it possible to pump 10-joule-class and 100-joule-class high-power industrial solid-state lasers and so will help boost production efficiency during laser processing of metallic materials.

Lasers are broadly classified into two groups: CW (continuous wave) lasers that continuously emit light at a constant intensity and pulsed lasers that repetitively emit pulsed light at very short time intervals. CW lasers that continuously emit laser light are used for heat treatment such as laser welding and cutting and are widely in use for laser processing and machining. Pulsed lasers on the other hand have been developed for new laser processing applications different from those for CW lasers such as for surface processing of metals that utilizes shock waves generated by instantaneous irradiation of high-energy light pulses.

Currently, along with the increased output power of LD modules, solid-state pulsed lasers able to emit light energy of about 1 joule are also being developed, and some of these are already being used in laser peening for hardening metal surfaces.

Meanwhile, demands are on the rise for LD modules with even higher output power capable of pumping solid-state pulsed lasers that emit light energy of 10 joules or more to allow uniformly processing large surface areas all at once and thus increase the production efficiency.

Schematic view of solid-state pulsed laser setup

Solid-state pulsed laser emits laser light with energy amplified by irradiating low-power seed light onto the laser medium that is pumped or excited with LD modules.

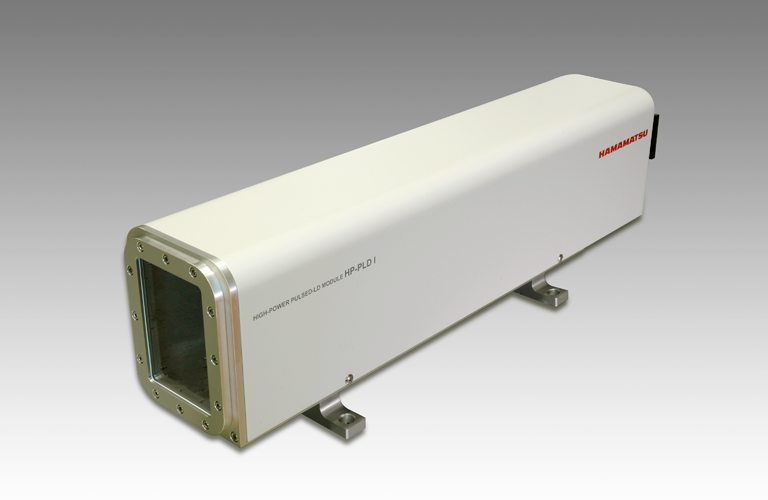

The newly developed products are compact pulsed LD modules consisting of multiple LD stacks and optical systems. We succeeded in developing two types of LD modules for industrial solid-state pulsed lasers. One type is for 10-joule class lasers and the other type with more LD stacks for higher output is for 100-joule class lasers.

LD module for 10-joule-class industrial solid-state pulsed laser system

Hamamatsu Photonics have already been working on developing pulsed LD modules for research applications. This time we successfully boosted the output power of LD stacks up to the world’s highest level by optimizing the LD bar design and using our advanced crystal growth technology. We have also fully established our unique technology for LD stack assembly that allows compact and efficient cooling. This means we can now offer LD modules that are compact yet provide high output power equivalent to other LD modules. Installing our newly developed LD modules allows pumping a solid-state pulsed laser system that emits light with high energy sufficient to process a large surface area all at one time and so will increase production efficiency. Furthermore, our new LD modules emit the laser light uniformly thanks to an advanced optical design. The uniform light beam emitted from the LD-pumped laser makes precision laser processing a reality.

LD module for 100-joule-class industrial solid-state pulsed laser system

Hamamatsu Photonics will continue developing LD module products that are ever more compact yet provide higher output power and with designs optimized for specific applications. We will also be working to open up new laser processing applications such as material coating-peeling and heat treatment by direct irradiation from our LD modules.