Berlin, September 27, 2016 The Ferdinand-Braun-Institut (FBH) presents novel developments and advancements of its diode lasers and UV light-emitting diodes (LEDs) at the international micro photonics fair. The event is hosted in Berlin from October 11-13, 2016. At the corresponding conference, Martin Maiwald presents the capability of mobile SERDS technology using FBH’s compact handheld probe with implemented dual-wavelength laser.

The FBH develops diode lasers and LEDs from the chip to the final module and increasingly advances these devices up to the operational system. This way, customers and partners can easily test their developments in the respective application. FBH’s customized diode lasers open up a variety of applications, from material analytics, sensors, and display technology to materials processing. Equally, UV LEDs with focus on the UV-B and UV-C spectral range can be adjusted flexibly to the requirements. Applications cover medical diagnostics and fluo-rescence spectroscopy as well as surface treatment and disinfection. FBH’s exhibits include:

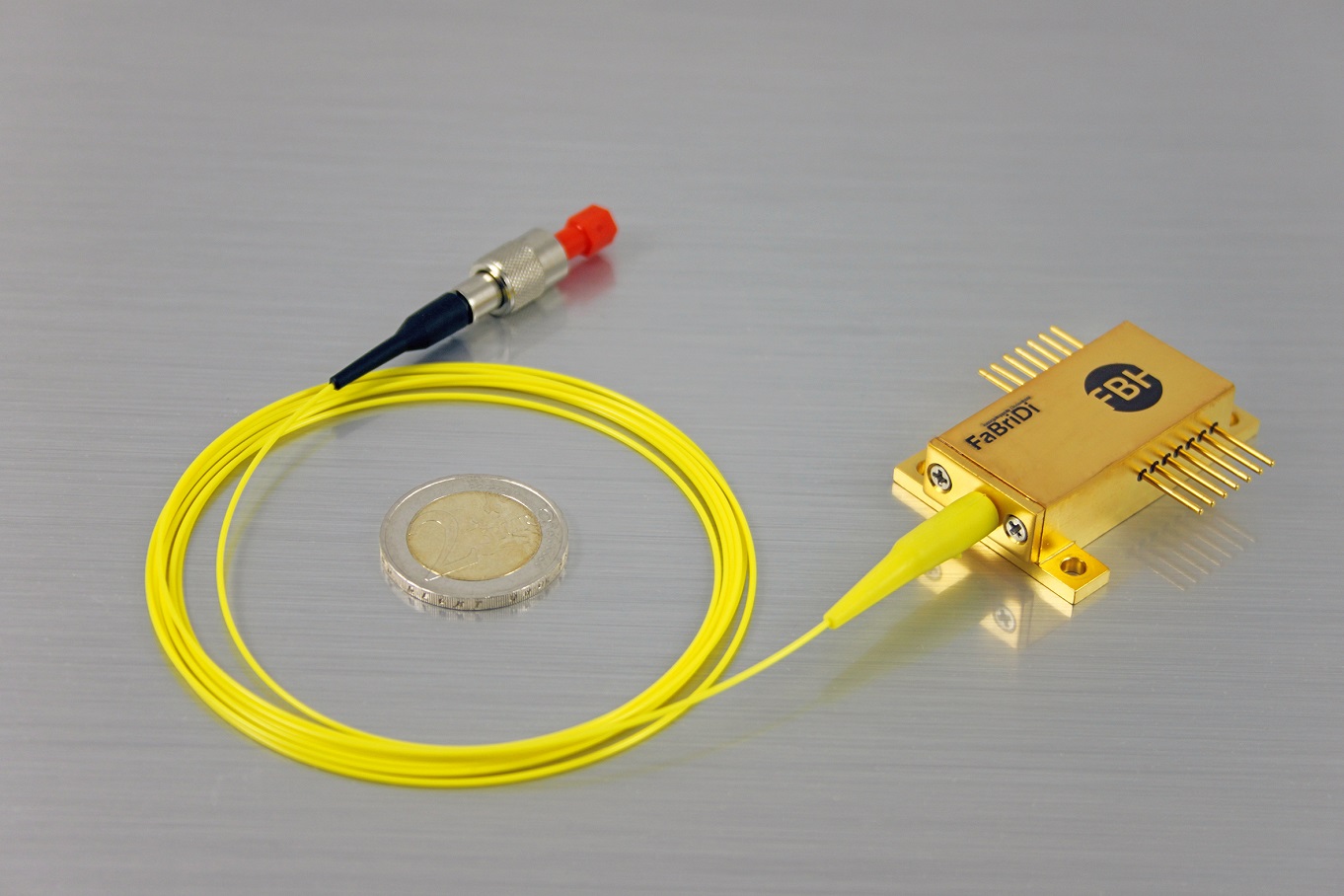

Industrial-suited diode laser modules with optical fiber connection

The FBH offers compact diode laser modules that allow customers to utilize high-brilliance laser radiation in their applications. Due to an integrated single-mode fiber (SMF) port the matchbox-sized modules can be easily installed into different systems. This way, efficient laser light sources are available for the near-infrared spectral range delivering diffraction-limited radiation with narrow bandwidth exactly where it is needed.

So far, three different module types have been demonstrated. For modules with both high output power >2 watt and high spectral radiance, FBH has expanded the available wave-lengths to the spectral range from 804 nm to 1064 nm. This setup can be transferred to wavelengths up to 1180 nm and is thus particularly suitable for pumping of solid-state lasers as well as for frequency doubling. Additionally, seed-laser modules emitting at 633 nm and 1180 nm have been demonstrated that deliver >20 mW output power ex fiber, featuring an optical micro-isolator and polarization-maintaining SMF (PM-SMF) at the output. A polariza-tion extinction ratio of more than 20 dB was shown for modules with PM-SMF output in the spectral range between 633 nm and 1180 nm. As a third design, an amplifier module emitting at 1180 nm with PM-SMF input and free-space output yielding >1 watt output power has been developed at FBH. By coupling the light of a seed-laser source into the PM-SMF, this radiation can be easily amplified. The principle is as well transferable to other wavelengths.

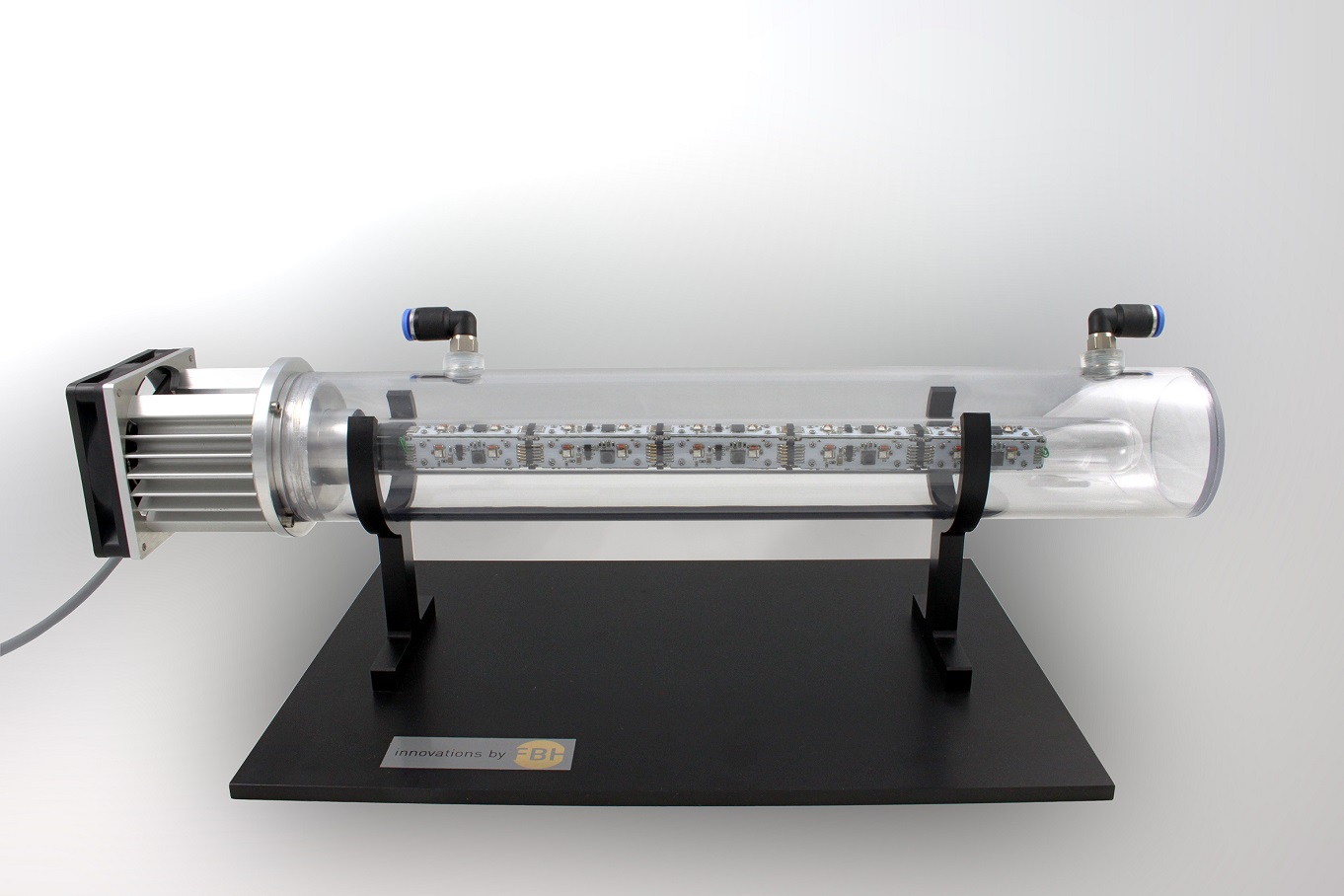

Rod-shaped module for water disinfection

Demonstrator UV-C LED module for water disinfection developed by the FBH (top: water supply, left: cooling)

©FBH/P. Immerz

All in just one device – tailored, flexible picosecond light impulse source

With PLS 1030, FBH offers a very efficient pulsed laser source that utilizes in-house devel-oped optical and electronical semiconductor components. The laser system is currently being optimized in a way that all functionalities are integrated in just one compact device, instead of so far two separate components, offering improved capability in addition. This all-in-one PLS 1030 delivers ultra-short light impulses at a wavelength of 1030 nm within an adjustable time range from 5 to 15 ps and provides freely selectable repetition frequencies, from the hertz to the megahertz range. Pulse peak performance is at more than 20 watts. Due to these properties, the laser source is ideally suited for application in materials processing, especially in connection with fiber amplifiers, for biomedical examinations based on fluores-cence spectroscopy, and for mobile LIDAR systems. The all-in-one device can be equipped with semiconductor components for 1030 nm and 1064 nm, but can be flexibly transferred to other wavelengths. It consists of a mode-locked laser with around 4 GHz repetition rate, an innovative pulse picker element, and an optical amplifier. Electronic control has also been developed by the institute using FBH gallium nitride transistors. As a result, short impulses can be flexibly selected from single to multiple serial pulses (burst mode) and amplified. All-in-one PLS 1030 is computer-operated in order to easily integrate it into various laser sys-tems, thus ensuring stable and user-friendly operation.

Higher brilliance and output powers for diode lasers and bars

The institute develops highly brilliant diode lasers in a wide variety of designs and packages, covering the wavelength range from 630 nm to 1180 nm. Single emitters with a stripe width of 90 μm, for example, reach peak brilliance results with 3.5 W/mm-mrad. In addition, smaller stripe widths deliver up to >6 W/mm-mrad (from 20…30 μm apertures) – again a record val-ue. For materials processing applications the FBH has developed custom arrays for spectral beam combining, consisting of five brilliant DFB lasers with 30 μm apertures, each yielding 5 W output power with 50% efficiency in a brilliant beam. The emitter-to-emitter wavelength spacing is 2.5 nm. Further activities at the institute aim at constantly improving efficiency, reliability, and output power. For example, recently record results have been achieved from novel QCW bars that demonstrate 60% efficiency when operated with 1 kW output power at 15°C. This efficiency value even rises to 70% at the same output power, when operated at a low temperature of -70°C.

Module for water disinfection with UV-C LEDs

FBH has designed a rod-shaped module for water disinfection purposes using in-house de-veloped 262 nm LEDs. This module aims at replacing conventional low-pressure mercury vapor lamps. UV LEDs score with higher lifetimes and are maintenance-free. Since they do not require toxic chemicals like mercury they are environmentally friendly in addition – mer-cury lamps need to be disposed safely after a few 1,000 hours operation. Wavelength and emission characteristics can also be adjusted specifically to the desired application. FBH’s demonstrator, which is shown for the first time at micro photonics, utilizes 40 LEDs each de-livering an optical output power of 1.7 mW; the medium irradiation intensity at a distance of around 2 cm is at approximately 2.0 W/m2. The geometry follows conventional flow-through water disinfection reactors, for example, for treatment of drinking or process water. This FBH setup is modularly expandable and can thus be adapted to various reactor sizes. Two LEDs form an assembly group with a constant current supply (max. 100 mA per LED) and a tem-perature termination for security reasons. Heat is dissipated via a heat pipe with attached fan.

Visit us at micro photonics fair in hall 7.2C, booth 207.