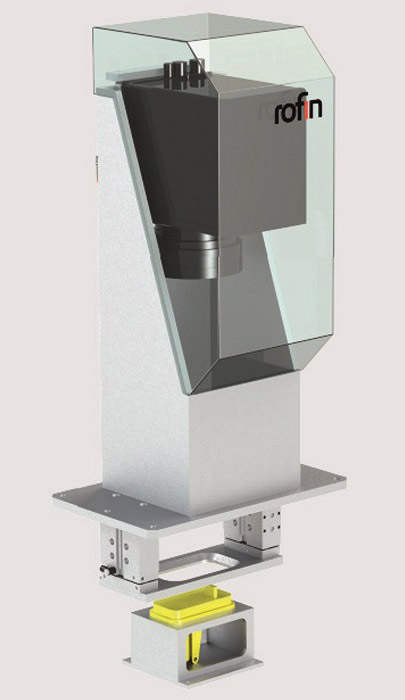

Munich/Germany, July 30, 2015: ROFIN continues the MPS laser workstation success. Its wide range of applications is extended by fusing of polymers. The system is based on the market-leading MPS laser workstation and the DILAS Compact Evolution laser sources and comes with application-specific control software.

The recent years have seen a continuously increasing demand for light-weight components made of polymers. For this reason fusing of polymers in complete system solutions with diode lasers has become more and more important. ROFIN already covers a considerable share of this expanding market with its DILAS diode lasers. However, more and more customers are asking for complete laser polymer welding solutions.

Fig. 1: MPS Compact – the complete system solution for laser polymer welding

Goal-driven development

The polymer welding system is either sold as a turnkey machine or as a functional kit consisting of laser, clamping unit and software for process control. Within less than a year the new polymer welding solutions are already turning out to be a great success.

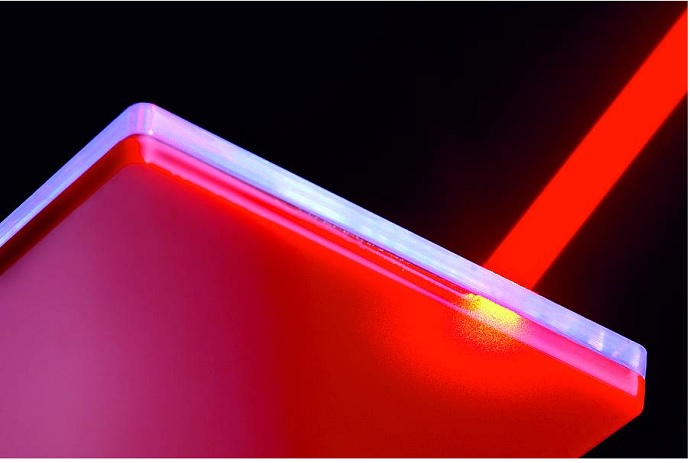

Fig. 2: Integration package Compact: Basic Integration package

HMI and clamping specifically designed for polymer welding

The systems are equipped with a special human machine interface for polymer welding and a work piece clamping unit working with either a pneumatic or a servo clamping drive, manufactured to the customer’s specific requirements. The control software for the joining process has been specially developed for polymer welding applications e.g. to deliver a setting signal and level for process control and quality assurance. Data can be logged for process statistics and quality management.

Based on state-of-the-art components

The polymer welding solution is based on ROFIN’s MPS, a production proven, multi-purpose laser workstation with a multitude of installations worldwide. It houses a DILAS Compact Evolution laser, operating with 980 nm or 880 nm wavelength and a cw power of 150 – 500W. A pyrometric process control allows for a constant welding temperature and hence optimized results.

Fig. 3: Pressure tank for the automotive industry

The most flexible platform for challenging applications

With the recently extended MPS family, consisting now of the MPS Compact, MPS Flexible, MPS Rotary and MPS Advanced, ROFIN looks forward to creating truly outstanding solutions for challenging polymer laser welding applications in the near future.