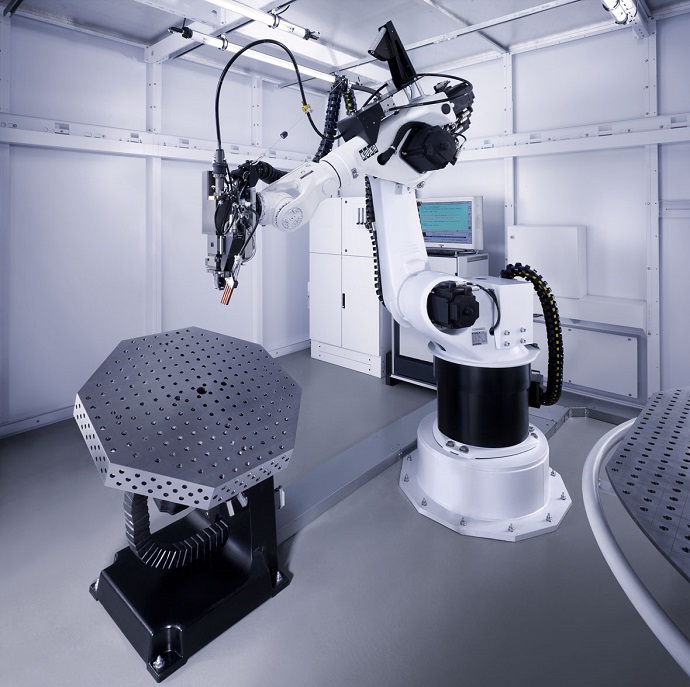

Ditzingen, October 21, 2014 – On display at the Euroblech 2014 in Hannover is TRUMPF’s new diode direct laser, the TruDiode 3006, in combination with the welding cell TruLaser Robot 5020. The laser system, thanks to its low investment and operating costs, offers an attractive way to make a debut in the world of laser welding. The special advantage of the diode direct laser is its relatively high efficiency level – as much as 40 percent. This makes it superbly thrifty in its use of energy. Additional cost savings are achieved by the laser due to its space-saving form and the resultant small footprint. Comparing laser welding with conventional procedures shows that the costs per item can be reduced by up to 80 percent. At the Euroblech, the robot cell is equipped with a TruDiode 3006 delivering 3 kilowatts of power. Depending on the demands of the operation, the laser system can also be equipped with a 2-kilowatt or a 4-kilowatt TruDiode laser.

With this new laser system, TRUMPF is appealing to the entire sheet metal processing industry. The laser is suitable for deep welding and heat conduction welding and thus substitutes for conventional welding techniques. In the deep welding process, the laser joins even materials that are several millimeters thick, thus achieving very high strength at the joint. During heat conduction welding, the new diode lasers create an even cleaner and more attractive welding seam than is already the case with the TruDisk lasers. It is worthy of note that passive cooling and the extended service lives of the diode laser modules promise great availability and long life cycles. The laser possesses emergency running characteristics so that laser output, even if one module should fail, is not reduced. In this way the continuation of the process is ensured; there are no power losses at the workpiece, and production can progress unhindered.

The new TruDiode 3006 diode direct laser achieves an efficiency level of up to a 40 percent, making it truly miserly in its energy use.

Photo: TRUMPF

New control panel for the robot cell

The TruLaser Robot 5020 has been aligned with the needs of 3D processing. It is equipped with the newest generation of controls and a new touchscreen user interface. The program sequence and the parameters can now be adjusted intuitively via the user interface, which has also been optimized to suit the touch-type controls. The complete robot cell contains – in addition to the robot itself and the laser with its processing optics – the positioning components and a protective cabin. The laser beam passes through a flexible laser light cable to the processing optics on the robot’s arm and ultimately to the workpiece.

The TruLaser Robot 5020 is modular in its design and thus can be configured to suit the individual customer. There is a variety of workpiece positioners available for selection, including the turntable and the rotational changer. The modular clamping system by TRUMPF, available as an option, offers a flexible solution so that workpieces differing in size and shape can be secured and welded with just a single device. Only a few motions at clamping system are needed to ready it for everything from simple sheet metal parts to curved profiles.

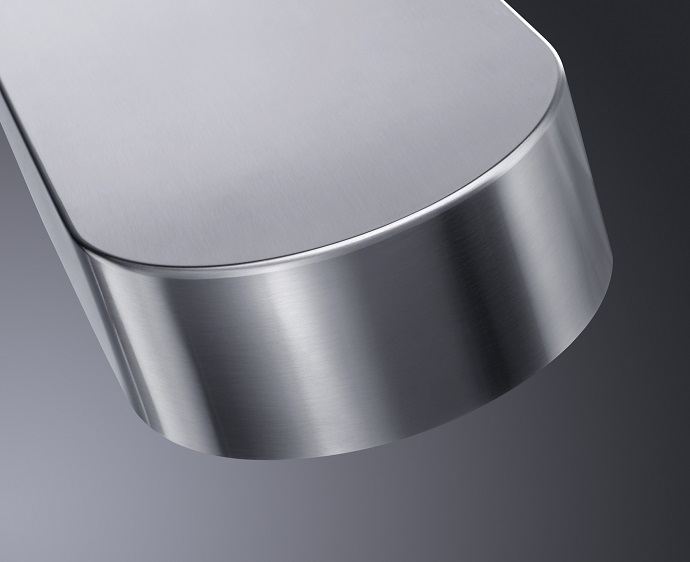

With the new generation of diode direct lasers, TRUMPF is focusing attention on deep welding and heat conduction welding. Shown in the photo is a laser-welded chain guard.

Photo: TRUMPF

The laser system with the new TruDiode lasers is available worldwide.