Ditzingen, August 12, 2013 – Greater accuracy, process reliability and user-friendliness – TRUMPF has enhanced its LensLine sensor system by combining it with an RFID (radio frequency identification) lens. The LensLine condition monitoring function improves the reliability of cutting processes implemented using 2D laser machines and reduces the frequency of lens cleaning.

When machines are using high laser power to cut sheet metal, dirt particles accumulate on the focusing lens in the laser cutting head. To ensure that the cutting process consistently delivers reliable, high-quality results, the machine operator has to check the lens at regular intervals, and if necessary clean or replace it. This normally involves a visual inspection, in which the operator removes the lens from the cutting head and looks for signs of contamination. These are not easy to detect in the case of transparent deposits. The enhanced condition monitoring function of TRUMPF’s LensLine sensor system can perform such tests faster and more accurately. At the press of a button, the system analyzes the degree of soiling and informs the operator if the lens needs cleaning or replacing. The condition monitoring test can also be carried out automatically at predefined intervals.

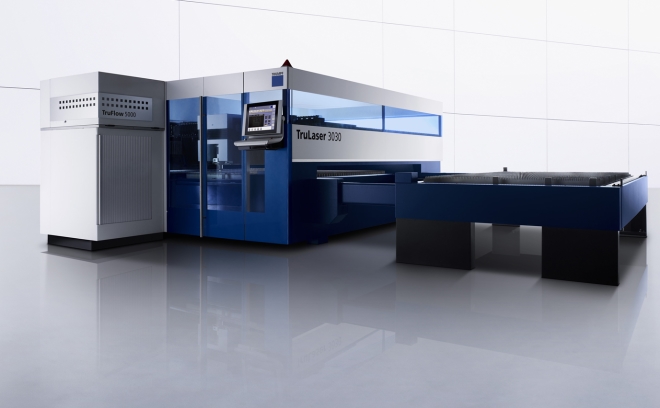

Tru Laser 3030

The new RFID lens is a standard feature of all TRUMPF TruLaser Series 3000 machines with a CO2 laser.

Photo: TRUMPF Group

As of July 2013, the new RFID lens is a standard feature of all TRUMPF TruLaser Series 3000 machines with a CO2 laser. A version for the TruLaser Series 5000 will be presented at Blechexpo 2013 – the international trade show for sheet metal processing. The RFID chip attached to the lens records condition monitoring data and other information such as the number of the times the lens has been cleaned. This method provides more accurate measurements than the previous LensLine system, and has the added advantage of being more objective than a visual inspection. A simple traffic-light system is used to display the test results on the machine operator’s console: green = OK, yellow = cleaning recommended, red = cleaning or replacement required. In this way the operator knows exactly when the lens needs to be cleaned and can optimize the cleaning cycle without having to resort to timeconsuming visual inspections or preventive maintenance. Thanks to a schematic display that provides a complete overview of the lens cleaning cycle, the operator only has to intervene when it is absolutely necessary. In total, the LensLine solution permits customers to cut cleaning times by up to 40 percent.

Another advantage of the new LensLine RFID technology is that it increases the reliability of the cutting process by ensuring that only lenses with the correct focal length are installed in the machine, in the correct orientation. The enhanced LensLine sensor system not only delivers objective, accurate measurements of the degree of lens soiling but also provides additional protection if the lens is not cleaned at the prescribed intervals. If dust particles accumulate beyond a certain concentration, there is a risk that the lens will absorb too much laser energy, causing it to overheat and in the worst case start to decompose. LensLine detects the first signs of this thermal degradation process and responds within a few milliseconds by switching off the laser. Once the lens has been replaced, the cutting process can be continued safely.

For more information: