Jul 03, 2013

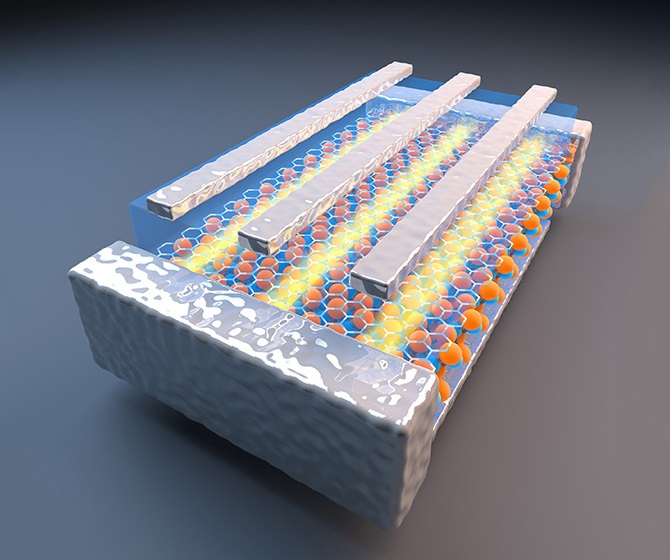

A layer of graphene can reduce the working temperature in hotspots inside a processor by up to 25 percent – which can significantly extend the working life of computers and other electronics. An international group of researchers, headed by Chalmers University of Technology in Sweden, are the first in the world to show that graphene has a heat dissipating effect on silicon based electronics.

“This discovery opens the door to increased functionality and continues to push the boundaries when it comes to miniaturising electronics,” said Chalmers Professor Johan Liu who heads the international research project.

Modern electronic systems generate a great deal of heat, above all due to the constantly increasing demand for more and more functionality. It is important to be able to remove the heat generated in an efficient way to maintain the long life of the system. One rule of thumb is that a 10-degree Celsius increase in working temperature halves the working life of an electronics system.

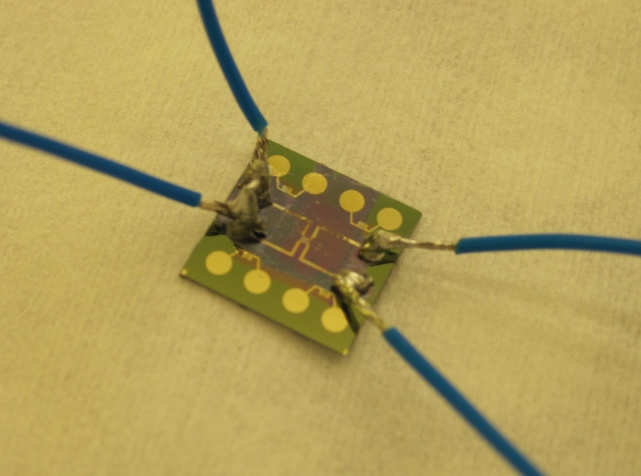

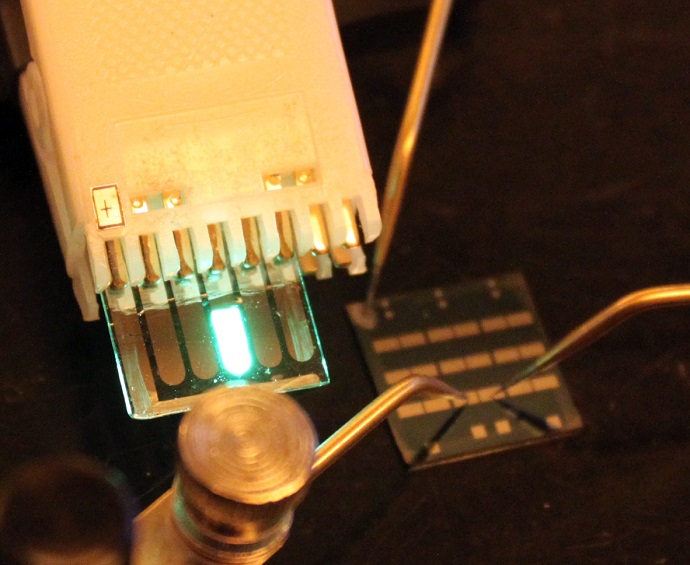

During the study, the researchers focused on reducing the temperature in the small area where the electronics work most intensively – such as inside a processor, for instance. These tiny hotspots are found in all electronics. Size wise, they are on a micro or nano scale, in other words a thousandth of a millimetre or smaller.

“The normal working temperature in the hotspots we have cooled with a graphene layer has ranged from 55 to 115 degrees Celsius. We have been able to reduce this by up to 13 degrees, which not only improves energy efficiency, it also extends the working life of the electronics.”

Efficient cooling is a major challenge in many different applications, such as automotive electronics, power electronics, computers, radio base stations and in various light emitting diodes, or LED lights. In automotive electronics systems, any single device in the ignition system can pump out up to 80 W continuously and in transient stage up to 300 W (within 10 nanoseconds). LED devices can have a thermal intensity almost on a par with the sun, up to 600 W/cm2 due to their extremely small size.

Superior cooling of electronics can deliver tremendous advantages. According to a study in the USA based on data from 2006, around 50 percent of the total electricity used to run data servers goes on cooling the systems.

The research, that has been undertaken in partnership with the Hong Kong University of Science and Technology, Shanghai University in China and Swedish company SHT Smart High Tech AB, has been published in the scientific publication Carbon.

Read the article: Thermal chemical vapor deposition grown graphene heat spreader for thermal management of hot spots

About graphene

Graphene, a single layer of carbon atoms, is stronger than steel yet lightweight and flexible. Electrons flow far more quickly through graphene than silicon. It is also a transparent electrical conductor that combines electrical and optical properties in an exceptional way. Graphene is a very good thermal conductor, ten times better than copper.

There are several methods of producing graphene that can be scaled up to industrial level. For electronics applications, high quality graphene can be produced using a method called chemical vapour deposition.