17 December 2013

A new discovery, by researchers at the University of St Andrews on why plastic solar cells work so well, could lead to better solar panels that are less expensive and more efficient.

Professor Ifor Samuel and Dr Gordon Hedley of the School of Physics and Astronomy, have discovered that a fibre-like arrangement of molecules is responsible for making some materials more efficient at converting the sun’s light into electricity than others.

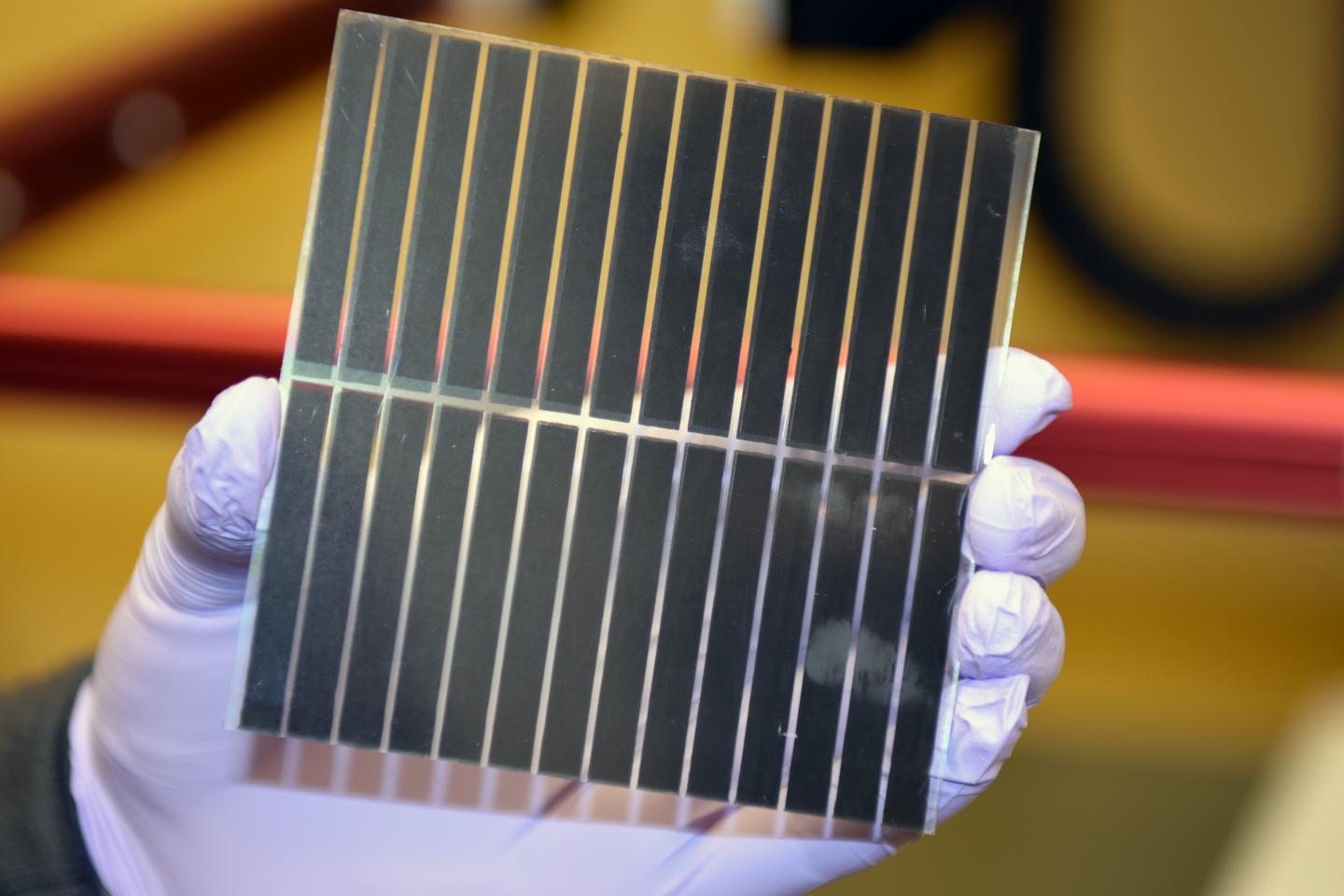

The discovery could improve how coatings on windows, or on curved or flexible surfaces, work to convert solar energy into electricity.

Plastic solar cells offer the prospect of simple fabrication and hence low cost, but their efficiency needs to be improved. They are typically made by blending two materials together.

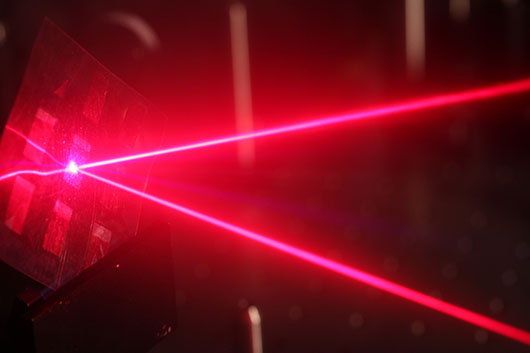

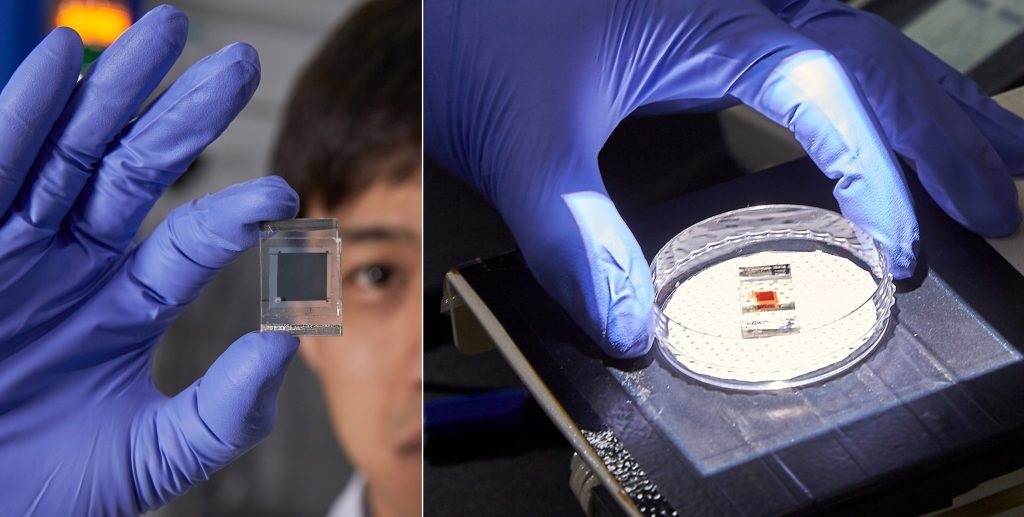

Using a combination of sophisticated laser measurements and very high resolution microscopy, the team were able to see the differences between a highly efficient and a less efficient solar cell.

They found that the materials were arranged in a fibre-like structure in the efficient solar cells, but as tiny balls in the less efficient cells.

The results are important because they suggest how to make even better solar cells. They are published in the journal Nature Communications.

Professor Samuel said: “The results are important because they suggest how to make efficient, low cost solar cells.”

Team member Dr Hedley added: “Seeing fibre-like structures was an interesting surprise.”

Organic solar cells are a promising renewable energy technology made of a thin (100 nanometre) layer that absorbs most incoming sunlight. The absorbing layer is a mixture of a light-absorbing plastic and a football-shaped carbon molecule.

The solar cell is fabricated by dissolving the two materials in a liquid and then depositing them onto a substrate. Current record efficiency organic solar cells are competitive with amorphous silicon photovoltaic cells.

The ability to solution-process organic solar cells enables fabrication using scalable industrial printing techniques such as spray-coating or screen-printing, offering up the possibility of thin, large-area, low-cost and flexible solar cells that can find uses where traditional silicon solar cells cannot.