Telecommunications connections must transport an unimaginable amount of data in real time over long distances. To feed source signals into the fiber optic cable with as little loss as possible, telecommunications companies monitor lasers’ performance data using laser beam profilers equipped with infrared cameras from Allied Vision.

Stadtroda, May 3, 2016 - Throughout history, humans have used optical signals for communication — from smoke signals to maritime light signals to modern communications media. The amount of data that must be transmitted in real time has risen incessantly, requiring the development of ever more powerful methods of transmission. In the age of the Internet and multimedia, laser beams serve as information carriers, thanks to a transmission capacity of more than 100 terahertz. Fiber optic cables are particularly well suited for transporting these optical signals and are far superior to classic copper cable in terms of bandwidth. In fiber optic-based network technology, light impulses with wavelengths of 1,300 nanometers and 1,550 nanometers (nm) have prevailed, as material-specific light losses of fiber optics are the lowest at these values.

Short-wave infrared radiation in view

Anyone who uses a mobile phone connection to watch online videos or television, or to use other services, expects the most distortion-free picture and sound quality possible. In order to ensure stability of the laser signal being sent, telecommunications companies use laser beam analysis devices called profilers. For effective laser use, monitoring and compliance of parameters such as beam position and size, power, and laser beam profile are of the utmost importance. Radiation scattering loss as well as different angles of incidence should be avoided when light signals are being coupled in the cable. With a fiber diameter of approximately 6 µm, bundling and directing the beam so that the coupling efficiency —meaning the relationship of the original beam to coupled performance — is optimal, represents a challenge. Live measurements of decisive parameters position telecom providers to be able to continually calibrate the beam and thus to optimize performance.

CINOGY Technologies GmbH in Ruderstadt Germany is a provider of high-quality laser beam characterization systems. Their laser beam profilers for the near infrared range, where telecommunication wavelengths fall, are based upon modern InGaAs (Indium-Gallium-Arsenide) sensors and are equipped with infrared cameras from Allied Vision. In the short-wave infrared range, beam profilers based on InGaAs-sensors are especially well suited for laser measurement. Since CCD and CMOS-sensors can only be used for wavelengths up to 1,100 nm maximum, InGaAs-sensor-based cameras expand the measurable wavelength range up to 1,700 nm.

CINOGY installs either the Allied Vision Goldeye G-008 SWIR (320x256 pixels) or the Goldeye G-033 SWIR (640x512 pixels) infrared camera in the laser beam profiler, depending upon the resolution required. Both models use a SWIR (short-wave infrared) InGaAs FPA sensor and are sensitive within the spectral range from 900 nm to 1,700 nm.

Thanks to a standard Gigabit-Ethernet-interface with an integrated power supply via Ethernet, as well as comprehensive input/output control options, the cameras can be integrated into the complex CINOGY laser beam profilers, operated, and controlled with no problem. The cooled sensors inside the camera for laser beam characterization enable an increase in sensitivity while maintaining low background noise, even with long exposure times.

Visualizing the laser profile

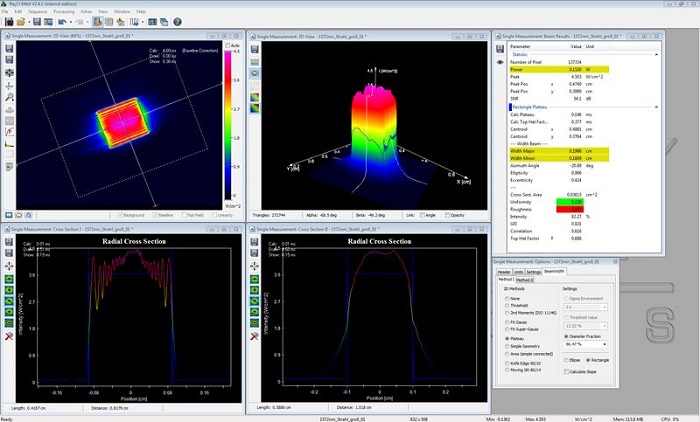

The laser beam is pointed directly onto the InGaAs sensor and can then be analyzed. Analysis of the data captured by the camera takes place using RayCi analysis software, developed by CINOGY Technologies. The program enables continual monitoring of beam parameters, such as coupling efficiency, in real-time measurement. If there are undesired structures in the beam, the laser profile displays signal loss live in the system. In order to measure performance stability, values are measured over a defined time period and compared with one another.

Decisive parameters are visualized in various two-dimensional profiles that reproduce the form and profile of the beam. Color-graded scales highlight the different characteristics. Side view as well as plan view can be selected. Moreover, the software offers an XML-RPC interface for remote software control. This enables efficient and simple integration of beam analysis into external applications. Easy implementation into different system platforms via XML commands sets this interface apart. For example, RayCi can be controlled using LabView applications, scripts or Excel. Dynamic Link Libraries (DLL) for various programming languages are also available that allow integration into very specific applications.

Complex systems and simple applications

“With InGaAs-sensor-based laser beam characterization systems built on, it is possible for users in the field of telecommunications to carry out laser beam analysis and optimization in the infrared range, which is not possible with systems based on CCD or CMOS sensors,” said Andy Kaemling, Managing Director of CINOGY Technologies, emphasizing the choice of Goldeye camera models from Allied Vision to equip the profilers. However, infrared cameras are not used only in complex systems. In the simplest case, the laser is simply “fired” at the camera’s sensor and the camera transforms the infrared light into a visible recording of the laser“, said Kaemling.

Laser beam characterization systems based on InGaAs sensors are already in use worldwide. CINOGY Technologies is currently developing a new measurement system conceived primarily for the infrared range; infrared cameras from Allied Vision will be an integral component.