Ditzingen, November 27, 2018 – TRUMPF has re-engineered the TruLaser Series 1000 from the ground up. These machines can now be automated across the board. The TruLaser Series 1000 also handles many cutting-related processes autonomously to drive down part costs. Equipped with a robust laser and proven functions such as collision protection, these machines cut sheet metal in a process-reliable way. And the intuitive operating concept reduces training time. Beyond that, TRUMPF added new features such as protective glass monitoring and BrightLine fiber. Previously available only in higher 2D laser classes, they serve to optimize processes and boost machine efficiency.

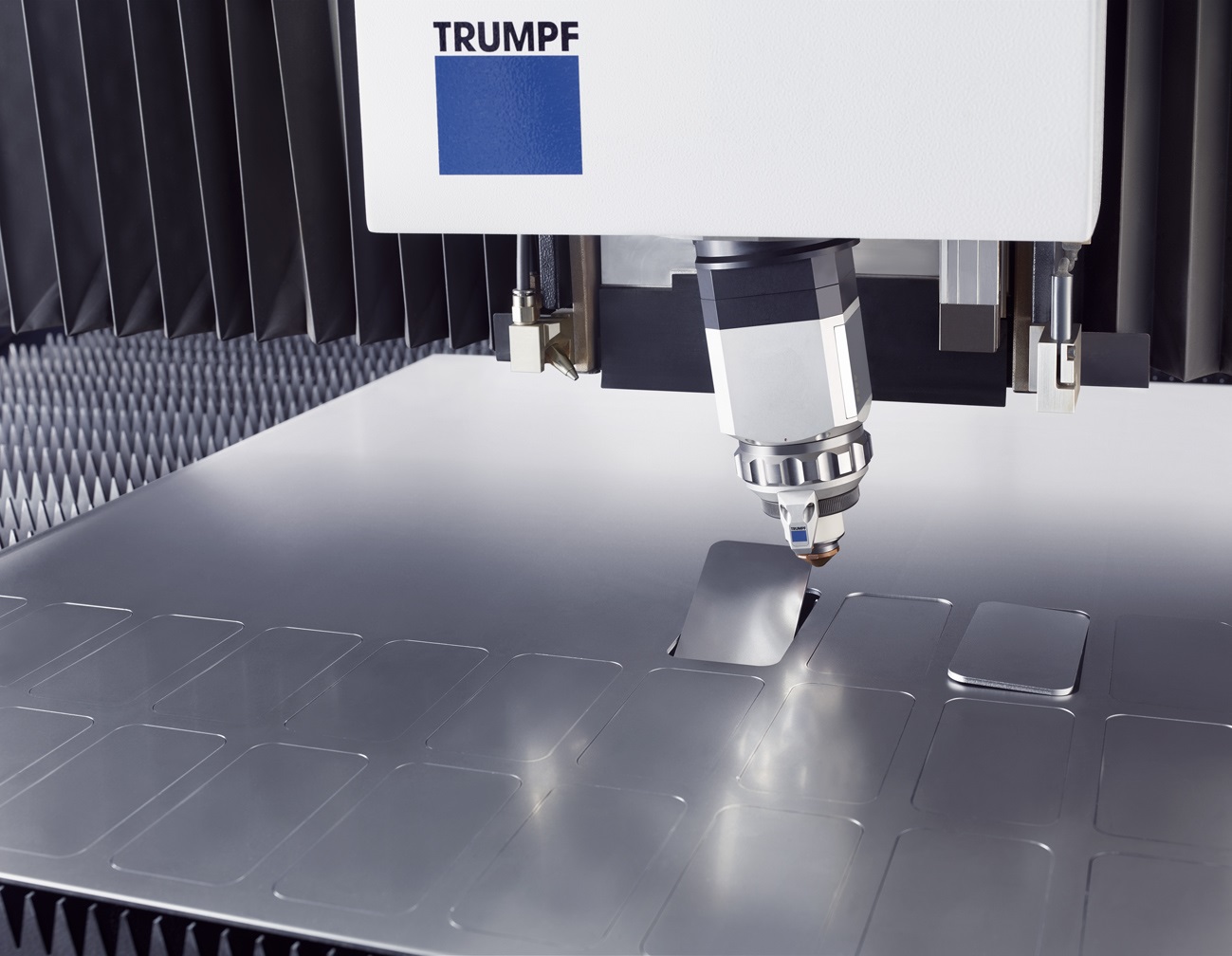

Collision protection

The cutting head deflects if it collides with a tilted part.

Photo: TRUMPF

Reliable job handling

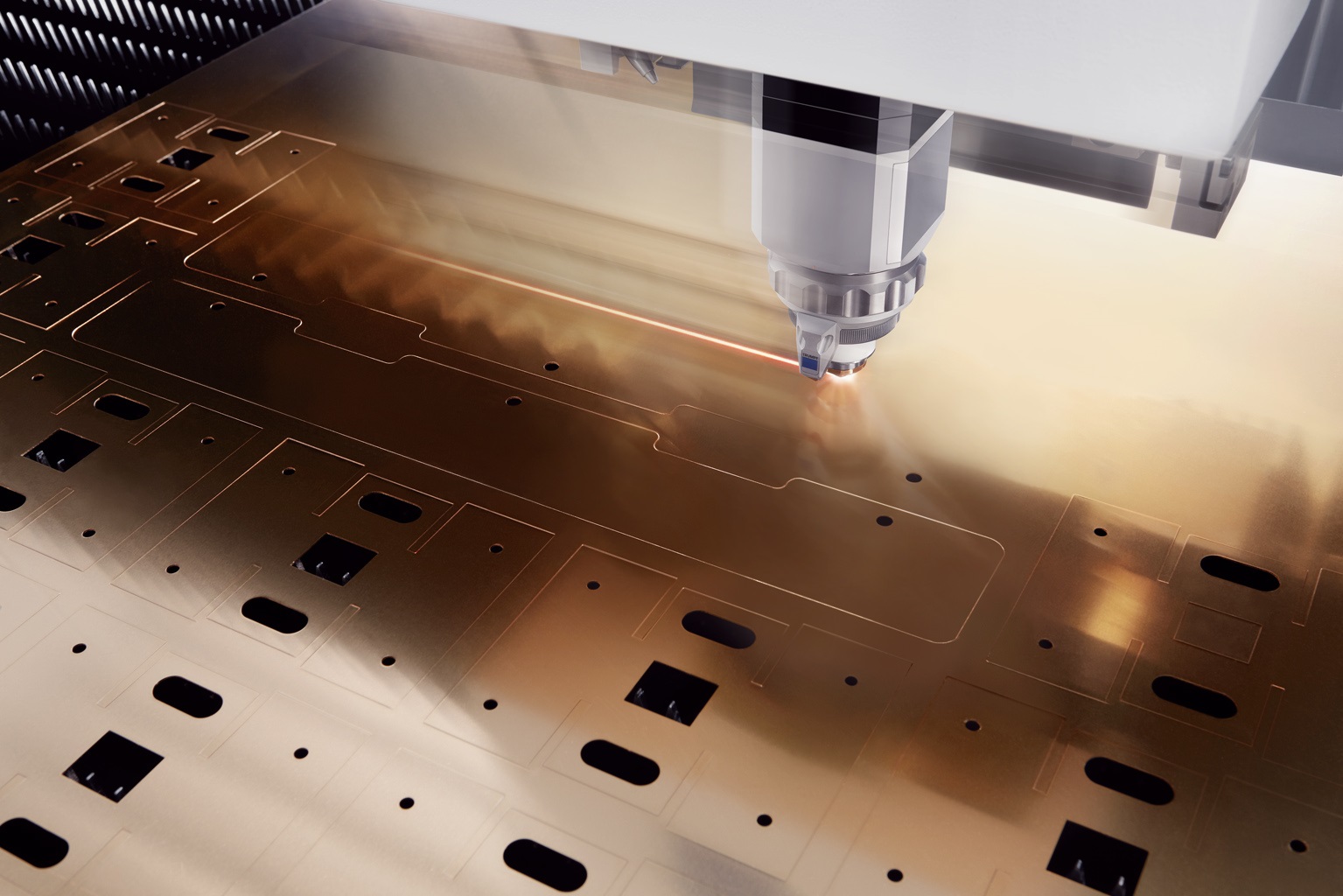

The new series consists of two types of machine, the TruLaser 1030 fiber and the TruLaser 1040 fiber with work areas three and four meters long, respectively. The TruDisk solid-state laser operates at constant power and is insensitive to reflections off copper, brass and other materials that reflect when cut. TRUMPF ships these machines out with data for cutting many commonplace materials and thicknesses of sheet metal. It enhances their process reliability - they can even cut copper with nitrogen. Machines with a four-kilowatt laser are equipped with BrightLine fiber. With this function, they can cut thick mild steel in a process-reliable way. In the event of a collision with tilted parts, a special protective mechanism deflects the cutting head to prevent damage to the cutting head and the machine. The TruLaser Series 1000 deposits slag and small parts in five pull-out drawers below the machine's frame.

Non-ferrous metals

The TruLaser Series 1000 cuts non-ferrous metals such as copper in a process-capable way. The TruDisk laser is insensitive to reflections.

Photo: TRUMPF

Lower part costs

This re-engineered line of TRUMPF machines is far more dynamic than its predecessor. Positioning speed is up from 85 to 140 meters per minute. This speed is down to the design of the machine's body, which combines a rigid machine frame with a lightweight motion unit and powerful drives. The machine cuts all materials and sheet thicknesses with the same cutting head. It changes nozzles automatically thanks to the optional nozzle changer. Sensors monitor the optics' protective glass and let the operator know when it is time for a replacement. Visual inspections are a thing of the past. All this reduces the machine's setup time. The TruLaser Series 1000 also saves time during the cutting process. The PierceLine feature reduces piercing time by up to 80 percent and protects the machine and material. These machines operate very energy-efficiently with an average power consumption of 13 kilowatts for the 3-kilowatt laser and 14 kilowatts for the 4-kilowatt laser. They also come with more energy-conserving features, as do their periphery modules.

Multi-touch control panel

The TruLaser Series 1000 features a new 18.5-inch multi-touch control panel.

Photo: TRUMPF

Easy to operate

The TruLaser Series 1000 features a new 18.5-inch multi-touch control panel. It displays the most frequently used menu items at the top level. If the operator interrupts an operation, the control unit enables processing to resume at the same point. The monitoring capability is not limited to the protective glass: Other sensors track the condition of components that impact the machine's cutting performance. A traffic-light readout on the control panel called 'the Condition Guide' indicates the status. It also offers guidance when the operator needs to take action. Flow charts make it easier to forecast actionable events and provides a more efficient way of scheduling maintenance work.

Automated nozzle changer

The TruLaser Series 1000 automatically changes nozzles to the correct type.

Photo: TRUMPF

Comprehensive automation

A semi-automatic pallet changer is a standard feature. The operator can prepare new sheets, while the machines are operating. The operator can also sort and unload cut sheets parallel to the cutting process. Users may also opt to equip the TruLaser Series 1000 with automated LiftMaster components. They load raw sheets and remove the cut sheets. TruLaser Series 1000 machines may also be connected to the compact TruStore storage system or to a large Stopa storage system.

Mobile machine operation, smart data utilization

The MobileControl app serves to operate the TruLaser Series 1000 using a touchpad situated near the machine. TruTops Monitor software tracks the machine's status continuously and notifies the operator in the event of a malfunction. The TruLaser Series 1000 affords users the opportunity to access the machine's digital enhancement. It contains five apps that assess machine data and deliver the results to users. AXOOM, a TRUMPF subsidiary, provides the cloud platform for processing these data. The apps provide an insight into tool and material usage and display the current machine status to users on the go.