June 26, 2018

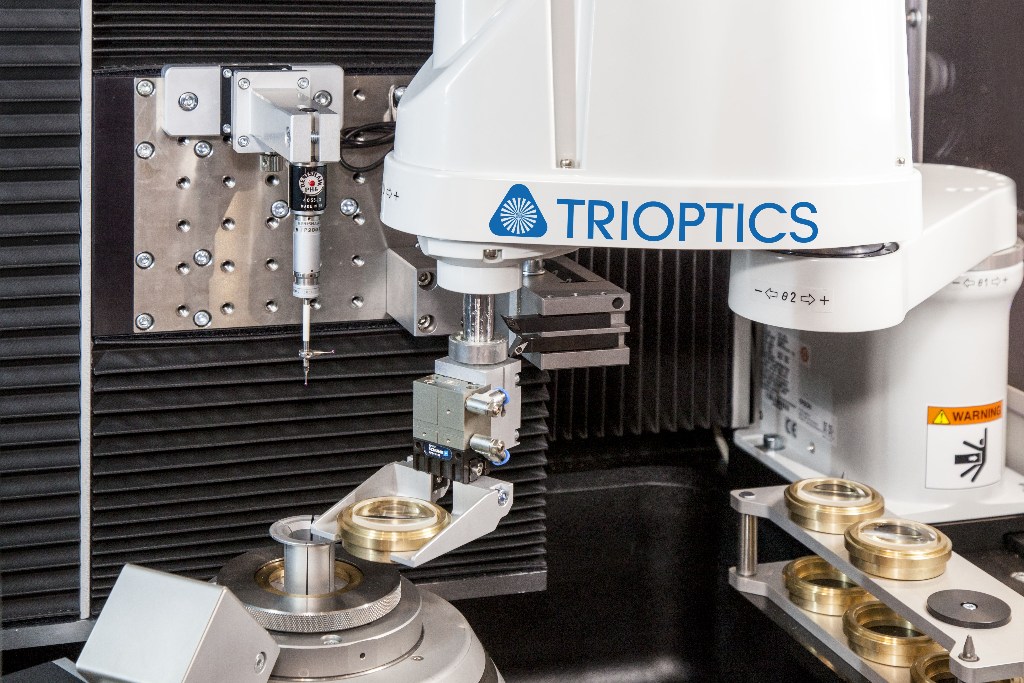

At the Optatec trade show in Frankfurt and for the first time ever in Europe, TRIOPTICS pre-sented robot-based automation solutions for loading the OptiCentric® 100 centration in-spection system and the ATS 100 alignment turning station for volume production.

For many years, TRIOPTICS has sup-plied automated systems to increase the efficiency of optics production. This is especially true for all solutions used to center and inspect lens systems. Dr. Patrik Langehanenberg, product manager for the OptiCentric® centra-tion inspection systems, explains: “There are a number of reasons for our focus on automation. One reason is that it increases the process reliabil-ity of our systems. Unfortunately, in many processes, operators are the limiting factor for accuracy and pro-cess time. Here, robotic processes allow improvements.” As a result, many processes in the OptiCentric® systems and in the ATS alignment turning station have been automated for years.

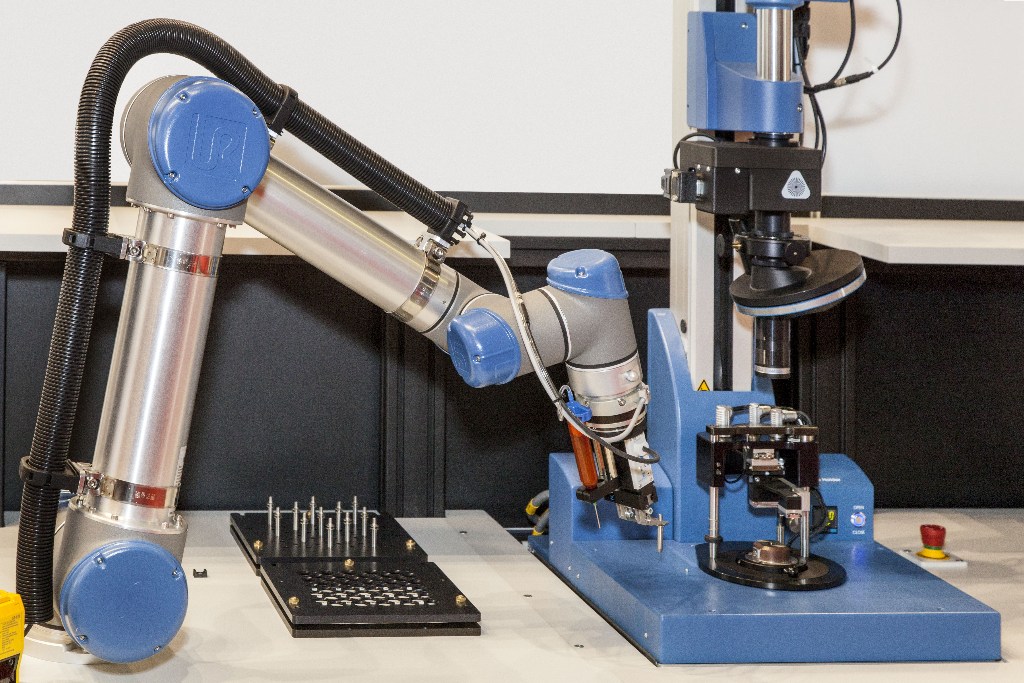

The robot loads the ATS 100 with a mounted lens. Immediately afterwards, the alignment and turning process begins.

Now TRIOPTICS is taking automation to the next level. “In volume production, operators used to insert the lenses manually and then start the pro-cess,” reports Dr. Christian Buß, product manager for ATS. “Now we use robots that do the loading and unloading process in one operation while the operator does other jobs or loads lens trays into other systems.”

TRIOPTICS’ engineers have in fact developed cutting-edge products, which was demonstrated by lively customer interest at the Optatec in Frank-furt, where both solutions were showcased. Cus-tomers were particularly interested in the direct integration of the robots in the relevant process. This ensures operational stability. The wide range of options – integration in various systems, for all kinds of applications and varying lens diameters – also impressed many visitors. Dr. Buß summarizes the development this way: “With these prod-ucts, we offer another, much-requested option that helps achieve increases in utilization and output in the production of a large variety of lens systems.“