March 22, 2016

Materials scientists and physicists at Lehigh have demonstrated a new method of making single crystals that could enable a wider range of materials to be used in microelectronics, solar energy devices and other high-technology applications.

The researchers reported their discovery Friday, March 18, in Scientific Reports, a Nature journal, in an article titled “Demonstration of single crystal growth via solid-solid transformation of a glass.”

The breakthrough, said the researchers, opens the way for glasses and other solid materials with disordered atomic structures to be made in single-crystal form as is silicon, the world’s leading semiconductor material.

In single-crystal form, the solids would possess the superior properties required in high-tech applications. These applications, the researchers said, include lasers and light-emitting diodes (LEDS), in which epitaxial-growth layering of extremely thin single-crystal films on a substrate is used to make semiconductor devices.

Single crystals of silicon are grown through melting, said Himanshu Jain, one of the paper’s four authors. But melting causes many other highly useful materials to decompose or change composition and lose their utility.

“The boundaries between the tiny crystals in polycrystalline materials are weak or bad links and give the materials undesirable properties,” said Jain, the T.L. Diamond Distinguished Chair in Engineering and Applied Science and professor of materials science and engineering at Lehigh.

“A single crystal, having no boundaries, has superior properties. It is stronger mechanically in corrosive environments, it is electronically superior and it transmits light well.”

Jain’s group used a novel heating strategy to convert glass into a single crystal without having it first pass through a gaseous or liquid phase and without the creation of unwanted crystals, or nuclei.

“In this first unambiguous demonstration of an all-solid-state glass [to] crystal transformation, extraneous nucleation is avoided…via spatially localized laser heating and inclusion of a suitable glass former in the composition,” the group wrote in Scientific Reports.

The lead author of the Scientific Reports article, Dmytro Savytskii, is a research scientist in the department of materials science and engineering at Lehigh. The other authors are Brian Knorr, an assistant professor of physics at Fairleigh Dickinson University who received his Ph.D. in physics from Lehigh in 2014; and Volkmar Dierolf, distinguished professor and chair of Lehigh’s physics department.

Applying just enough heat

In a single crystal, said Jain, all the atoms of a material are arranged in a perfectly ordered 3D lattice structure. To make a large single crystal of silicon, scientists take a tiny seed of single-crystal silicon and pull it up from melted silicon. The atoms from the melted silicon deposit on the seed in a lattice structure. Depending on the speed at which the crystal is pulled, a small or large single crystal of silicon emerges as the melt cools.

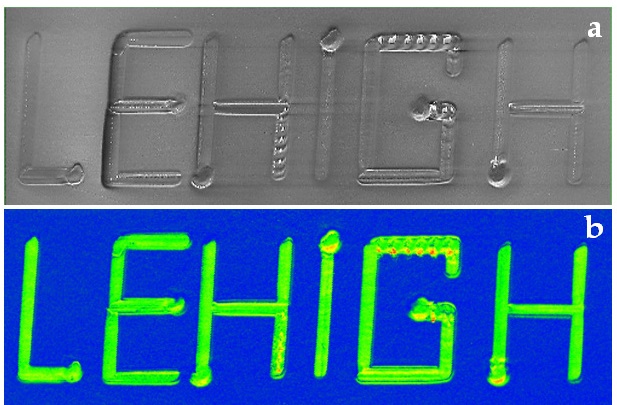

Jain’s group developed a contrasting method to make a single crystal of an antimony-sulfide (Sb2S3) chalcogenide glass. To induce the formation of a crystal inside the glass, the group uses a laser to heat the glass from the ambient temperature to a crystallization temperature well below its melting point. Electron-diffraction and microscopy color mapping then enables the researchers to detect the orientation of atomic configurations and to prove single crystallinity at different places on the sample.

The formation of the crystal, Jain notes, occurs as the solid glass is heating up and not, as is the case with silicon, when its melt is cooling. This is readily observed in scratches that run across the glass through the single crystal formed by the laser. Any melting of the glass would smoothen and eliminate the scratches.

“Once we make the single-crystal line,” said Jain, “we backtrack to get additional parallel single-crystal lines and eventually a single-crystal-layer surface on top of the glass. We can stitch these lines to convert the entire glass surface into a single crystal.”

The group’s goal, said Jain, is to apply enough heat so that the disorganized atoms in the glass organize into just one single crystal without triggering the nucleation of unwanted crystals.

“We want just one nucleus to form. If we get multiple nuclei, we end up with a polycrystalline ceramic material with undesired properties.”

To prevent extraneous nucleation, the group uses a focused laser to limit the volume of glass that is heated and allow only one nucleus to form. That nucleus is quickly grown into a single crystal.

“We show that unwanted additional nucleation can be avoided by decreasing the volume of the heated region and growing the crystal by moving the laser beam at a sufficiently fast rate such that there is no time for forming extraneous crystals,” the group wrote in Scientific Reports.

The group also came up with a second strategy that relies on a glass of a predesigned composition of antimony, sulfur and iodine (Sb-S-I). As the single crystal begins to form and grow, iodine moves out of the crystal into the neighboring glass, where it acts to suppress nucleation.

The project has been funded for six years by the U.S. Department of Energy.

Story by Kurt Pfitzer