(PresseBox) (Dortmund, 08.12.2016) Though the success of any demanding laser application hinges on the light source used, the application's beam shaping capability is also a decisive factor. With its new Fused Silica optics for high-performance laser diodes up to 500 W per bar, LIMO Lissotschenko Mikrooptik GmbH has delivered the key technology for the trend towards increasingly powerful laser outputs.

The new high-performance laser systems with outputs upwards of 10 kW are currently in high demand for hardening, additive manufacturing, cutting and welding applications, for example. "But all of these applications require high-performance optics which convert the raw beam from the laser source into the most symmetrically shaped beam possible," says Dr. Oliver Homburg, Director of Product Management for Optical Solutions at the Dortmund-based LIMO Lissotschenko Mikrooptik GmbH. As laser output increases, the task of concentrating the laser light into a high-energy precision beam with high efficiency and extremely low losses becomes more and more challenging. To deliver the best possible performance and beam quality, the new High Power BTS from LIMO is therefore produced from ultra-pure Fused Silica with a minimum content of oxygen-hydrogen bonds.

"As the OH concentration increases, more of the concentrated light is absorbed," Dr. Homburg notes. "That's why we use an ultra-pure Fused Silica with the lowest possible concentration of OH bonds. This glass absorbs virtually no laser light, which means that hardly any heating takes place, even in the case of high laser outputs." When standard materials are used, the BTS can heat up, which in turn results in deteriorated optical properties (the "thermal lens" effect) and reduced performance. In contrast to this, the new High Power BTS made of Fused Silica remains thermally stable – even in industrial high-performance applications – and thus provides reliable functionality across the entire laser system. Thanks to the ultra-pure Fused Silica, extremely high transmission rates (better than 98%) are achieved.

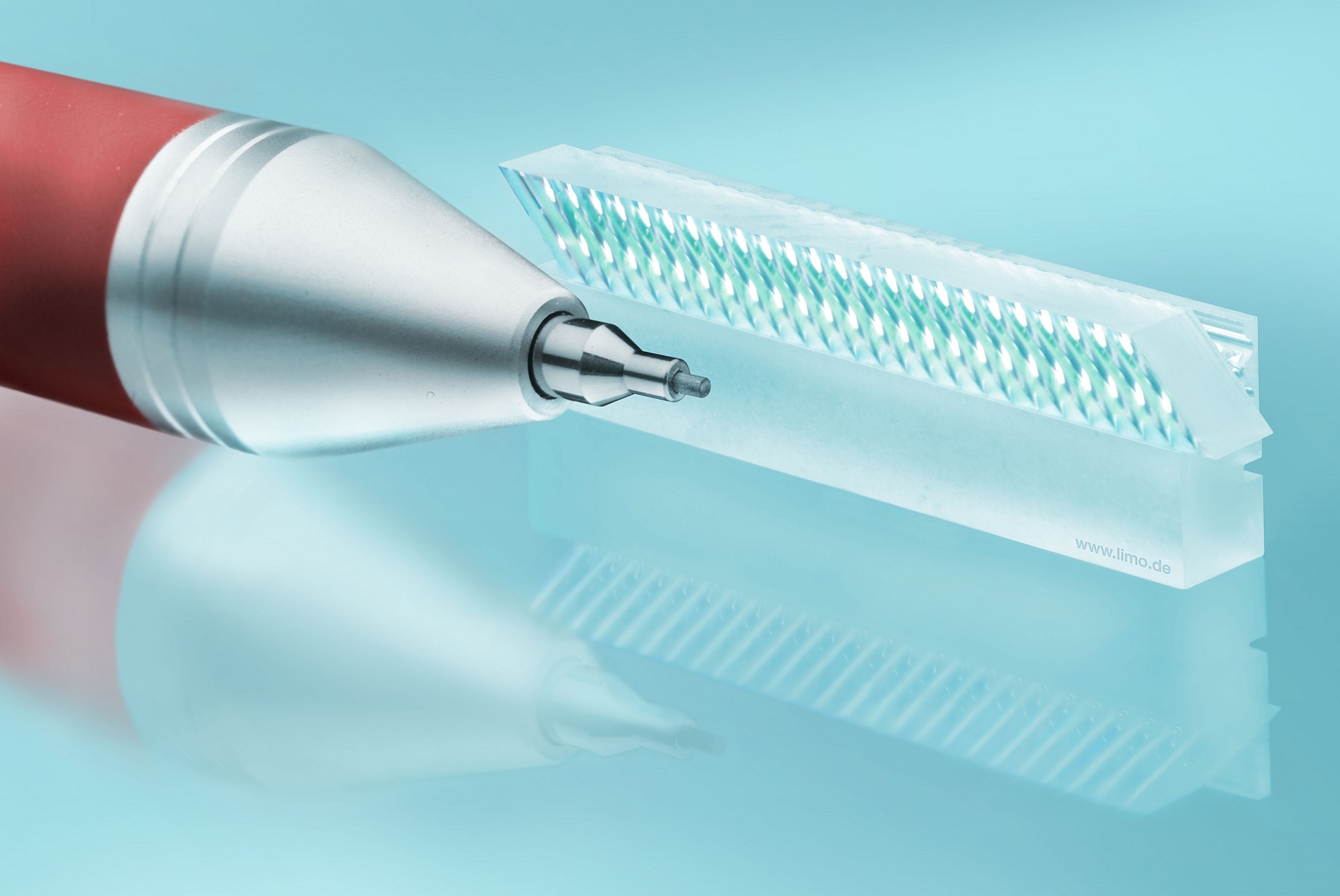

The new BTS can be used to both couple laser light into a circular fiber and produce a free laser beam. The system comprises the Fast Axis Collimator FAC160 (which is optimized for short focal lengths) and a diagonal lens array for a 90° rotation of the laser beam. It comes preassembled on a glass block (bottom tab) for easier handling. With a pitch of 200 or 400 µm, the system is capable of coupling up to 50 emitters with an output of approximately 250 to 500 W per bar and a 50% fill factor.

"Clearly, there are many other processes in which the High Power BTS can provide improved application results and, as a result, critical market advantages," says Dirk Hauschild, Vice President for Marketing at LIMO. "For example, I could also see the possibility of using the Fused Silica BTS to coat metals more efficiently and with higher productivity than before, or even for enhanced metal finishing. Come talk to us about the new application possibilities for direct processing using diode lasers!"

For more information, LIMO will also be on hand at the SPIE Photonics West trade fair in San Francisco (USA) from January 31 – February 2, 2017 at booth # 1740 in South Hall.

Laser optics: The key to success

Fused Silica BTS for high-performance laser beams

Thermally stable: The new High Power Beam Transformation Systems (BTS) from LIMO are made from ultra-pure Fused Silica and can be used to shape beams from diode laser sources with an output of up to 500 W per bar / Photo: LIMO / Markus-Steur.de