March 21, 2016

COLUMBIA, Mo. – In the race to design smaller handheld devices and smartphones, a key factor is decreasing the sizes of components. As the demand for thinner and lighter microelectronic devices increases, manufacturers often are limited by how oddly shaped the energy sources must become to make them conform to the smaller space. Now, researchers at the University of Missouri, have developed a method of transferring an energy source to virtually any shape. Using an efficient laser-writing technique, MU scientists can help smartphone manufacturers potentially fabricate energy storage units like microbatteries and micro fuel cells that are more environmentally friendly, highly designable and thin.

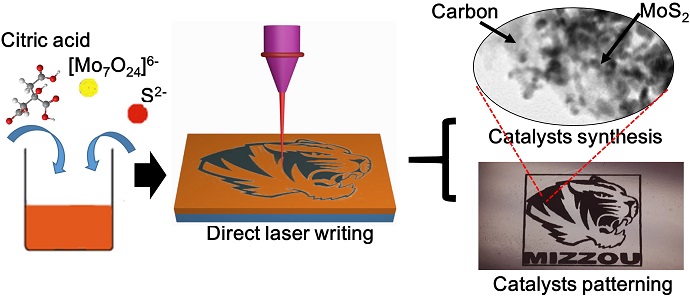

“The direct laser writing (DLW) method and technique has seen a rapid advancement in the past decade,” said Jian Lin, an assistant professor in the Department of Mechanical and Aerospace Engineering in the MU College of Engineering. “The main goal of our research was to find an efficient and cost-effective way to integrate nanostructures with micro energy storage units for applications in micro-electronics. Our lab decided to test whether catalysts could be synthesized and patterned on any surface by a one-step laser processing method to produce microbatteries and micro fuel cells in the shapes dictated by computer programs.”

Direct Laser Writing Method

The process developed by Jian Lin and his team is universal, allowing them to synthesize and pattern any possible catalysts into any chosen size and shape.

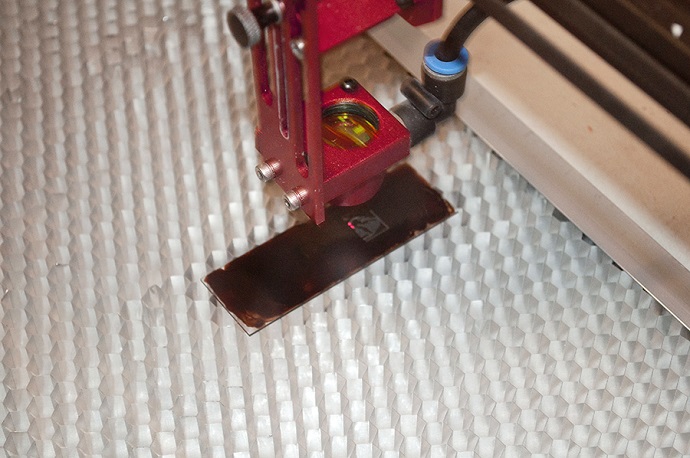

With this in mind, Lin and his team, including Heng (Henry) Deng, a doctoral candidate at MU, set out to prove their theory. They adapted the DLW method to synthesize and pattern hybrid nanocatalysts, or fuel sources, into complex geometric shapes. Using computer-controlled laser writing that uses higher heat and pressure, the scientists were able to produce a surface that became electrically conducive and also has catalytic functionalities.

“This is the first step in manufacturing micro fuel cells that convert chemical energy into electrical energy and batteries that can integrate into microcircuits” said Lin. “Also this technique has been proven to produce microsupercapacitors. By honing the process, handheld device and smartphone manufacturers will be able to produce components in whatever shape or size they choose, greatly impacting the size of these devices. Also, manufacturers will be able to choose more environmentally friendly catalysts for generating energy such as hydrogen or oxygen, which are considered cleaner fuels. The possibilities will be endless.”

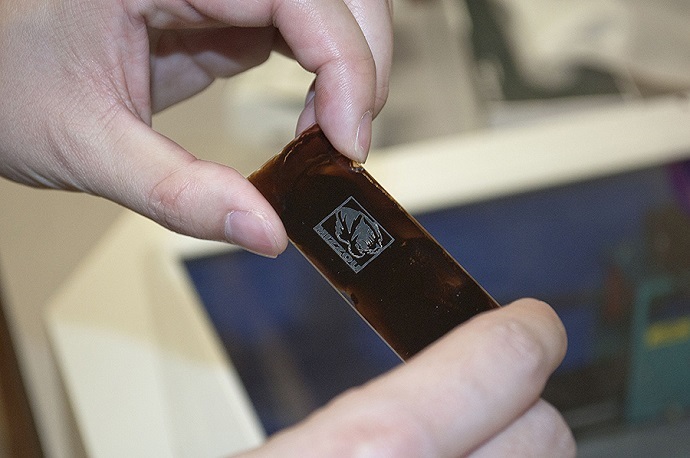

Fabrication of Nanocatalysts on Thin Substrates

Depiction of the DLW method in fabricating arbitrary patterns composed of MoS2/carbon hybrids. Credit: Publisher of Royal Society of Chemistry

The paper, “Laser induced MoS2/carbon hybrids for hydrogen evolution reaction catalysts,” recently was published in a special issue of “Emerging Investigators 2016: Novel Design Strategies for New Functional Materials” in the Journal of Materials Chemistry-A.