August 17, 2016

NIST scientists have devised and modeled a unique optical method of sorting microscopic and nanoscopic particles by size, with a resolution as fine as 1 nanometer (nm) for particles of similar composition.

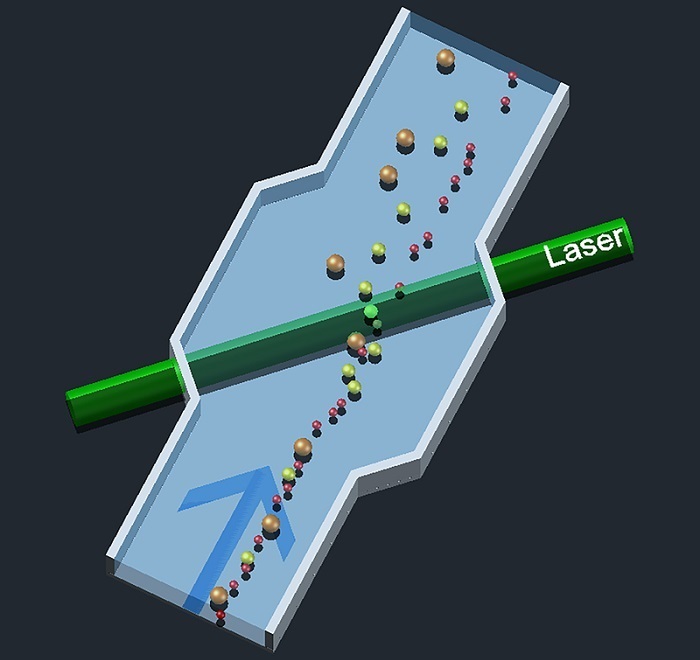

A stream of particles of various sizes enters the system at a single point, but the particles exit the system at different places, depending on their size. The process does not alter the particles in any way, so that those with dimensions of interest can be readily separated and analyzed. The sorting operates on a continuous input of particles, with the particles moving through the system in only a couple of seconds.

That kind of capability is of significant interest to climate scientists studying atmospheric chemistry and airborne contaminants, as well as to national security and health care. “For example, if you wanted to know whether someone had released spores or bacteria or even viruses into the air in a closed space, such as a subway system,” says John Curry of NIST’s Physical Measurement Laboratory (PML), “you could dramatically speed up the investigation by sorting, because a cubic centimeter of air can contain thousands of nanoparticles.”

The idea arose when “I got to thinking that there all these great tools that have been developed for atomic and molecular physics, but they haven’t really been applied to the study of particles,” says Curry, who co-developed the idea with PML colleague Zachary Levine.

Although individual particles in fluids have been manipulated by a different technology called “optical tweezers,” and optical patterns have been used to sort particles in microfluidic channels, comparatively little attention has been devoted to aerosols, where the scientists decided to focus their work. “One of the things that sets it apart,” Curry says, “is that it has a large volume compared to optical tweezers. We wanted something useful for batch processing, that could process a very large number of particles at the same time.”

“It became clear that the ability to sort by size was a primary concern,” Curry says. “Zachary and I started tossing around some ideas, and pretty soon we realized that setting up an optical standing wave, and then running a stream of particle-bearing air across it at an angle, was going to do the trick.” They determined the forces at work from first principles, and then subjected the model to two different kinds of rigorous numerical simulations.The results were published last month in Optics Express,* and NIST has filed a provisional patent application. A prototype device has not yet been developed.

The NIST system envisions a cavity (as small as 5 mm long, or much larger) with mirrors at both ends. A laser beam enters the cavity and forms a resonant standing wave, with regularly spaced regions of high and low optical field strength. Each high- or low-intensity region is about one-quarter of a wavelength wide. (See illustration above.) To model particles, the scientists used the well-characterized properties of polystyrene spheres, which are widely employed in nanoparticle research, at various diameters on the order of 200 nm. They assumed a flow rate of 1 mm per second, about 10 times faster than a typical microfluidic channel.

As a particle approaches the optical standing wave, the degree to which it “feels” the optical force -- and is thus deflected from its initial path -- is directly dependent on its size. The largest are affected earliest and displaced the most. Smaller sizes are deflected later and less. And some particles of a specific “magic” size move straight across the standing wave field with hardly any deflection at all.

“If the particle is around half a wavelength wide, closely approaching the same length scale as the spacing in the sinusoidal standing wave,” Levine says, “it’s going to have about the same amount of its volume in both low-intensity areas and high-intensity areas, resulting in a zero-force condition.” That phenomenon had been observed before, but largely overlooked in terms of its sorting potential.

Even small deviations from the “zero-force” proportions would be discernible in the particle path. “You could set it up so that you know exactly what kind of a regular sphere would pass right through the system,” Levine says. “But if an identical sphere had, say, an antigen bonded to it, you might be able to tell them apart even though the mass difference is only parts per thousand.”

Another potential benefit of the system, Curry says, is that with a variable-wavelength light source, it could be used as a reliable standard for measuring the size of nanoparticles in a way directly traceable to the SI: “Because the phenomenon directly links the size of the particle that makes it all the way through the optical field to the wavelength of the laser light -- which we can adjust and measure to high precision -- this system offers what may be the first way to connect particle size to a fundamental SI unit.”

Although the journal article focused on aerosols, the researchers have determined that the same system can be used to sort particles in liquid, including protein-like particles in water. Researchers in the life sciences need to be able to sort out the individual components of protein agglomerations, and the conventional method -- filtering -- is not ideal. “You can also use optical tweezers,” Curry says, “but the throughput is very low. Our system, by contrast, could process a million particles per second. In addition, a large number of these devices could be operated in parallel.”

* "Continuous-feed optical sorting of aerosol particles, "J. J. Curry and Zachary H. Levine, Optics Express. DOI: 10.1364/OE.24.014100