16 October 2015

asphericon now investing in new measurement methods, involving the absorption and reflection of optical coatings

asphericon has expanded its range in the production and measurement of high-quality optical coatings, with absorption and reflection now being measured more accurately than ever before with LID and CRD measurement systems. As a result, anti-reflexive optical coatings are able to be improved further, especially in high-performance laser applications. The company provides these measurement processes as a service, whether or not the substrates are coated by the company or elsewhere.

As managing director Alexander W. Zschäbitz explained: “We decided for this investment because our customers for high-performance laser systems have shown an increasing interest in these measurement methods. The new test procedures have confirmed the high quality of asphericon’s coatings. We can now document this level of quality for our customers as well. And we have been rounding out our range of services even more with the construction of a LIDT measurement station able to measure the laser-induced damage threshold.”

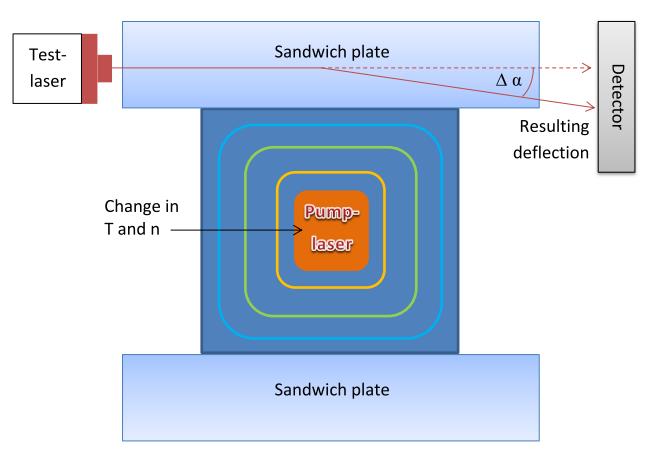

A laser is aimed at the optical components in the laser-induced deflection (LID) process. The beam’s absorption leads to a rise in the material’s temperature. This then leads to a change in the refractive index n (see Figure 1). The deflection of the laser beam, which is triggered by the refractive index gradient, can be detected by shifting the intensity of the beam as it hits the sensor. The goal of the asphericon measuring station is to determine with precision the volume absorption of transparent optical materials at wavelengths of 532nm, 940nm, and 1064nm.

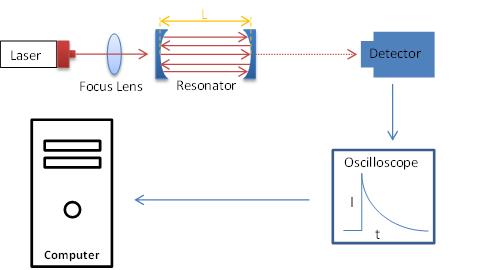

Schematic depiction of the CRD process

To determine the reflection of high-reflection laser mirrors (99.5% to 99.9995%), the Cavity Ring Down (CRD) Technique can measure the smallest levels of loss, reported in parts per million (ppm). This involves the determination of the photon lifespan or the exponential decrease in intensity in an optical resonator, composed of two highly reflective dielectric mirrors (see Figure 2). The asphericon measuring station is geared toward wavelengths of 355nm, 532nm, 940nm, and 1064nm, and a sample diameter of up to 25mm.