16 Jul 15

by Iben Julie Schmidt

As laser technology is developing, the range of applications for lasers, and thereby also the market, is growing. This is something the spin-out Norlase—with three DTU patents under the belt—is poised to exploit.

An image of the eye's retina produced with a special laser microscope is able to detect not only eye diseases, but also early stages of diabetes. And the better the image, the more precise and reliable the diagnosis. The quality of the image depends largely on the laser in the microscope.

Now, the start-up Norlase has developed a type of laser which not only produces sharper and better images, but is also an affordable alternative to competing lasers. CEO of Norlase, Peter Skovgaard, hopes that within a short period of time, many of the world's microscopes will be equipped with the laser.

"We have already delivered the first lasers to a company that produces components for these microscopes, and this is the first step into a major growing market. Imaging techniques are currently seeing rapid growth within biomedicine, where the improved laser technology helps develop new efficient methods involving reduced distress for diagnosis and treatment of a large number of diseases."

From infrared to visible light

The secret behind the new laser is an advanced semiconductor laser ensuring that the purity of the beam is maintained even at very high power levels. In addition, a simple but efficient device enables transforming the infrared light of the semiconductor laser into visible light. This opens up a range of new applications for the laser, which the DTU researchers responsible for developing the laser without hesitation call the world's best laser.

"We have conducted research into laser technology for more than 20 years, which is why we, in connection with an EU project, were asked to develop a green laser," says Paul Michael Petersen, Professor at DTU Fotonik.

"We discovered that by transmitting the beam from a powerful, but sufficiently pure semiconductor laser through a non-linear crystal, we could achieve the desired wavelength of 532 nanometers—i.e. green light. We had developed a method for transforming infrared light into visible light very efficiently. In fact, this method helped us develop the world's most powerful green laser based on diode technology," says Paul Michael Petersen in relation to the patented technology which today forms the basis of Norlase's product.

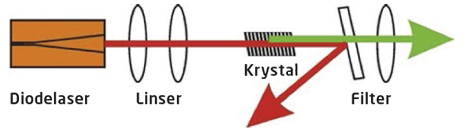

How Norlase's laser works

The laser is a diode laser performing at 1 μm (micrometres). What makes the laser special is that it can emit a high-power beam while maintaining high beam quality and purity. By transmitting the laser beam through a non-linear crystal, the laser beam is transformed into visible green light, in that two photons are transformed into one photon with half the wavelength and twice the energy. This means that the infrared light of the diode laser with a wavelength of 1064 nanometers is transformed into a wavelength of 532 nanometers, which creates the green light.

Specifications Size:

14 x 9 x 5 cm Wavelength: 532 nm Beam quality: M2 < 1.3 Cooling: Air-cooled

New colours, new possibilities

In addition to microscopy, the green laser is used to pump energy in, e.g., lasers for high-precision cutting of thin metal sheets. So currently, the laser coming out of a small compact black box is green, but it is only a first step. Norlase and researchers from DTU Fotonik are working together on developing a blue laser which has the potential of becoming an important component in future LED lighting—another big market. A blue-green laser is furthermore in the pipeline. This will provide new opportunities within remote sensing—i.e. performing measurements from a distance, such as from a satellite. A laser producing a yellowish light is also on the drawing board at Norlase. Its applications will include various types of dermatological treatments, such as removing skin contusions.

The best of two worlds

"This is a new platform technology with virtually unlimited potential. And although competition is fierce, our laser holds an interesting position on the existing laser market. At one end of the market are the small diode lasers found in, e.g., DVD players. They are inexpensive, but not particularly powerful. At the other end of the scale, you find highly advanced high-power lasers which, however, are also very expensive and very complex to design.

Our technology encompasses the best of two worlds: The starting point is a strong and not least future-oriented technology. In addition, we are financially competitive as our laser is easy to produce and less expensive than competing products while also being highly efficient," says Peter Skovgaard. Twenty years ago, he wrote his PhD dissertation on the key component of the laser, which is now integrated in Norlase's product. Since then, he has, among other things, contributed to the development of the spin-out Crystal Fibre, which is now a company with more than 100 employees operating under the name NKT Photonics.

Business collaboration enriches research

"Establishing a company such as Norlase, which is extremely closely linked to our core competencies, makes us stronger as a research institution, and this is particularly clear when we submit research applications," explains Professor Paul Michael Petersen and continues:

"My research group works closely with a large number of companies, which gives us a unique understanding of the market needs. It increases our focus on the quality and competitiveness of our research, and it offers valuable knowledge when choosing the direction for our long-term research activities. As a research institution, we can take chances in relation to the areas where we believe to see major technological progress in future. This is rarely possible in a private company. Nevertheless, it seems that the major breakthroughs in research typically occur when taking risks."

Edited article from DYNAMO no. 41, DTU's quarterly magazine in Danish.