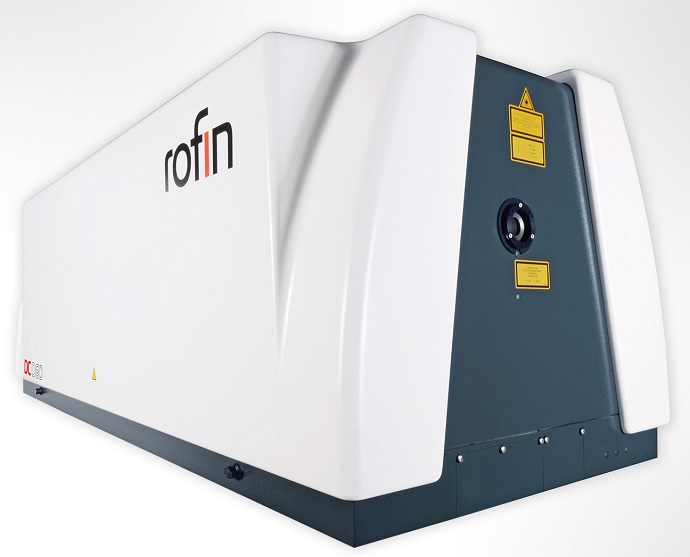

Hamburg/Germany, September 15, 2014: True to the motto“More power for cutting” ROFIN presents the DC 060, a CO2 Slab Laser with 6 kW cutting performance for the first time at this year’s EuroBLECH (Hall 11, Booth A46). ROFIN is continuing to develop its product portfolio for the cutting market towards higher cutting performances for thicker sheet metals and is the only laser manufacturer that offers CO2 as well as fiber lasers in this high power range.

„We are glad to enlarge our CO2 product range with this new model,“ states Thorsten Frauenpreiß, Managing Director of ROFIN-SINAR Laser GmbH. „This laser provides new possibilities for all cutting applications and is an ideal complement to our high-power fiber laser portfolio. We are convinced that we can further expand and strengthen our market position in the area of laser cutting."

ROFIN’s low-maintenance CO2 Slab Lasers are extremely service-friendly. The laser operates with only a few extremely durable components and does not need conventional gas recirculation – leading to a considerable reduction of lifetime costs. Furthermore, the energy saving standby operation leads to minimal energy consumption.

The entire DC Series is provided with the “Rofin Control Unit” (RCU) like all other lasers of the ROFIN Macro group. This control enables extended monitoring and control functions, resulting in improved pulse-to-pulse stability, manifold control and log functions including E-Service.

ROFIN’s CO2 Slab Lasers with output powers up to 8,000 W are in use at manufacturing sites all over the world. The excellent reliability, low maintenance, and superior beam quality attract customers from a variety of industries and regions.

The ROFIN Macro Group

The ROFIN Macro Group headquartered in Hamburg/Germany offers a wide range of high-power lasers. CO2 Slab Lasers as well as fiber lasers of high beam quality are integrated in cutting machines of numerous machine manufacturers worldwide but also demonstrate their benefits whilst laser welding. Q switched, solid-state lasers for surface treatment applications complement the laser solutions. The product portfolio is rounded off by intelligent system technology for scanner welding as well as for the welding of tubes and profiles.