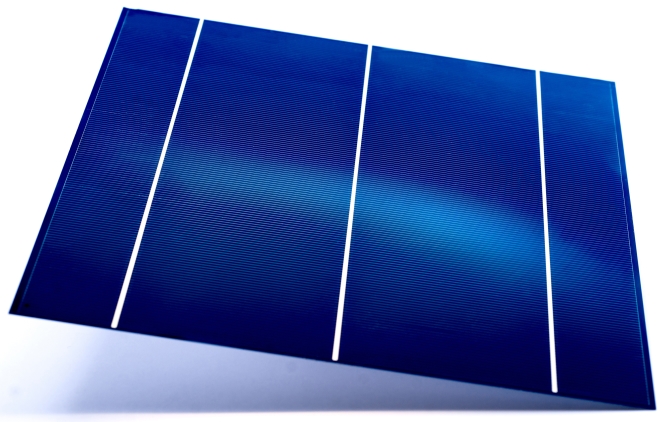

Leuven (Belgium), November 27, 2013- Nanoelectronics research centre imec announced today that they have developed large area (156x156mm2) i-PERC-type silicon solar cells using a new processing sequence based on laser doping from a thin atomic layer deposited (ALD) aluminum oxide (Al2O3) layer to realize the local aluminum Back Surface Field (BSF) and Ni/Cu plating to form the front contact. The cells achieved average conversion efficiencies of 20.2%.

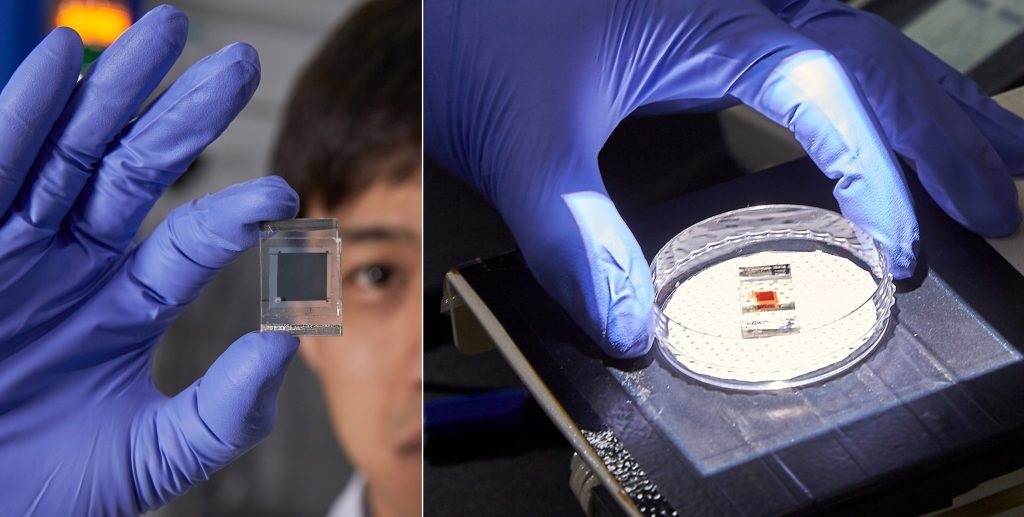

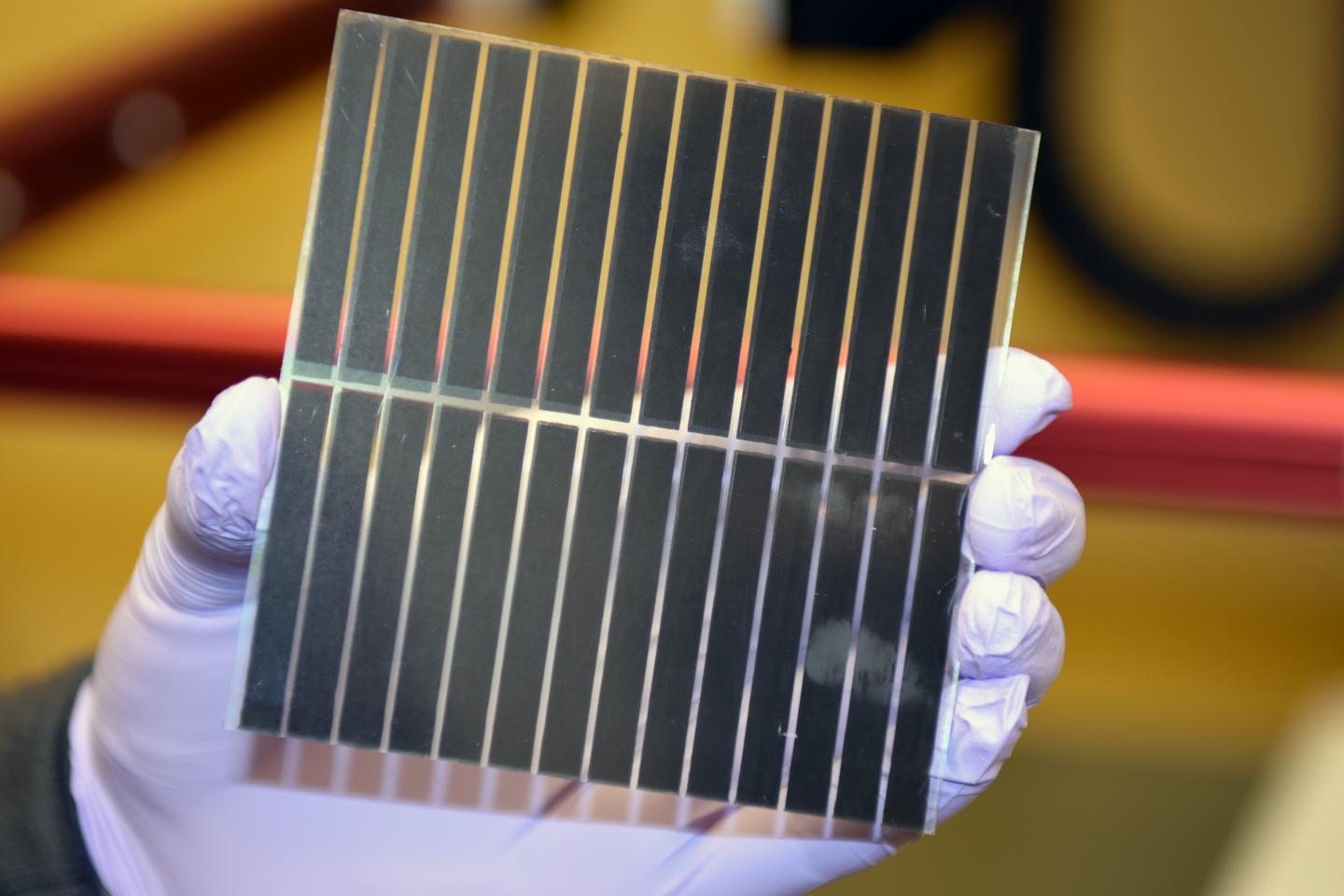

The new laser doping processing sequence eliminates the necessity of a firing step to create the local BSF in i-PERC solar cells. Combined with imec’s Ni/Cu plating sequence for front contact formation, it provides a low temperature metallization solution for i-PERC cells. By avoiding high temperature conditions, passivation degradation of the rear Al2O3 layer, as well as optical degradation of the rear dielectric/metal stack are prevented, resulting in improved solar cell conversion efficiency. Additionally to the performance benefit, this new process sequence is extremely simple because the thin ALD Al2O3 acts at the same time as passivation layer and doping source, while laser processing enables in one step the contact patterning and the local BSF formation.

The complete solar cell process was executed at imec and the resulting 156x156mm2 i-PERC silicon cells on p-type Cz-Si achieved an average conversion efficiency of 20.2%. Even though only low temperature anneal was used, the high Fill Factor of the cells (up to 80%) indicates an excellent contact quality.

“Cost-of-ownership and process simplicity are key factor for the industry to adopt new technologies,” stated Jozef Szlufcik, Si PV program director at imec. “Our achievement, implying a substantial simplification of the i-PERC manufacturing process, is an important step towards reducing the cost-of-ownership of i-PERC technology and as such, a milestone in bringing this high-efficiency technology for silicon solar cells to the market.”

These results have been achieved in the framework of the imec’s industrial affiliation program on advanced silicon solar cells, dedicated to developing high performance and low cost Si PV-technologies.

About imec

Imec performs world-leading research in nanoelectronics. Imec leverages its scientific knowledge with the innovative power of its global partnerships in ICT, healthcare and energy. Imec delivers industry-relevant technology solutions. In a unique high-tech environment, its international top talent is committed to providing the building blocks for a better life in a sustainable society. Imec is headquartered in Leuven, Belgium, and has offices in Belgium, the Netherlands, Taiwan, US, China, India and Japan. Its staff of more than 2,000 people includes more than 650 industrial residents and guest researchers. In 2012, imec's revenue (P&L) totaled 320 million euro. Further information on imec can be found at www.imec.be.