12.01.2015

Minna Hölttä

A light-emitting diode (LED) is a semiconductor component whose structural layers are designed and built in a way that makes them emit coloured light when electrical current passes through. Simple, yes?

'Producing a lamp that uses LEDs and shines a pleasant light is many times more complex than the manufacture of incandescent light bulbs, which only contain a simple wire filament,' ProfessorFilip Tuomisto points out.

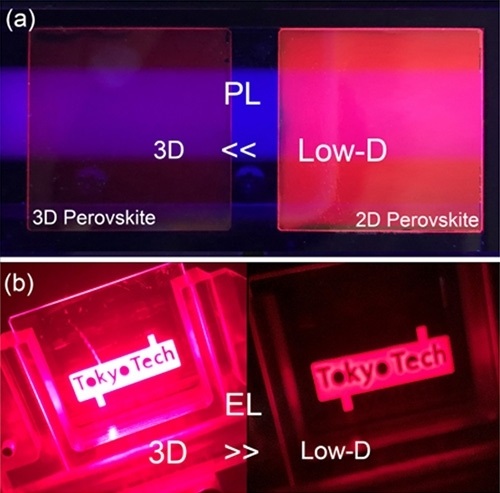

One complication involves the creation of white light, which pleases the human eye. The blue LED developed by Isamu Akasaki, Hiroshi Amano and Shuji Nakamura in the 1990s – a feat for which the trio recently received the Nobel Prize in physics – is a good start, but not enough by itself.

'The ideal solution would be to combine the blue with the red and green LEDs that were developed earlier. However, green LEDs are not efficient enough, so we have to come up with something else,' Tuomisto says.

At present, white light is produced by coating a blue LED with a layer of phosphorus that transforms some of the blue light into red and yellow. The combination of three colours appears white, but some light is wasted in the process, decreasing efficiency.

'Developing an efficient green LED would render phosphorus unnecessary. Another challenge is identifying why LED efficiency weakens after a certain current density is exceeded.The third problem is associated with optimising the output efficiency of light, which is created in a semiconductor material. To solve these questions, we could attempt to pull some unique trick out of our sleeve. But gaining a genuine understanding of LED behaviour as well as of the reasons underpinning their optical and electrical properties is the preferable avenue,' Tuomisto explains.

Atomic precision

Understanding LEDs demands a precise knowledge of materials. Filip Tuomisto focuses on studying semiconductor material point defects, i.e. anomalies in their atomic-level structure.

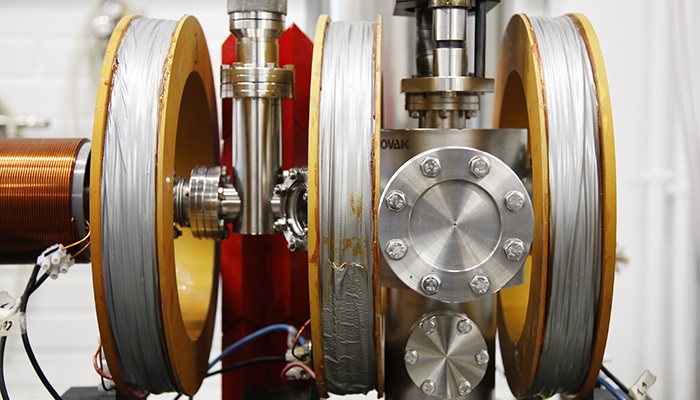

'An atom may be missing or in the wrong place, and these defects to a great extent determine the characteristics of the semiconductor and thus also the LED,' he explains and says that positron annihilation spectroscopy is a key method for studying these vacancy defects.

Development of the method, which is exceptionally sensitive to the identity and quantity of atomic-level crystal defects, started in Otaniemi as far back as 1958, and progress has been enormous in the past half-century.

'We're world leaders in the development and use of this method, and our work on the subject has also involved cooperation with recent Nobel laureates, among others,' Tuomisto says with a smile.

In addition to materials research, Aalto University also focuses on studying LED manufacturing methods and structures. The first reactors were acquired in the 1990s and, since then, the infrastructure has been improved through substantial equipment investments. In fact, Aalto is the only place in Finland with the capability to manufacture the semiconductor material layers, which are needed for blue LED components, from start to finish.

'When I started my doctorate in 2004, there was just a couple of guys tinkering with blue LEDs. Now, Micronova is home to a team that can control the entire chain from the gas bottle all the way to a finished LED and we can work with the top experts in the world,' says researcher Sami Suihkonen, who has worked in the Amano and Nakamura research groups.

Big risk, big opportunity

Tuomisto and Suihkonen both emphasise how important it is that the diverse expertise and technology required for LED development is found under one roof.

'Many experiments would not be done without this close cooperation,' Sami Suihkonen sums up.

'We don't need to settle with examining LEDs manufactured by others, as we can make our own and thus also experiment with more exotic structures,' Tuomisto adds.

In the last few years, Aalto researchers have explored issues like what causes components to weaken during use. This weakening is a substantial problem in not only LEDs, but also laser diodes, which are used in Blu-ray discs, for example.

'The experiments we performed on nitride materials demonstrate that the cause is attributable to hydrogen stored in vacancy defects. When enough current is directed into a laser diode, the hydrogen becomes mobile and the previously-harmless vacancy defects start to weaken the material's properties. This finding is so significant that it gained coverage in the field's international professional journals,' Filip Tuomisto says.

Could an efficient green LED also be created at Aalto?

'Yes, of course, but it's not all that likely,' Tuomisto and Suihkonen say and laugh.

'Unlike in the world of business, we have the opportunity to experiment with complex things and high-risk ideas. The probability of success is small, but, should everything fall into place, we can achieve truly great things.'

Positive cycle

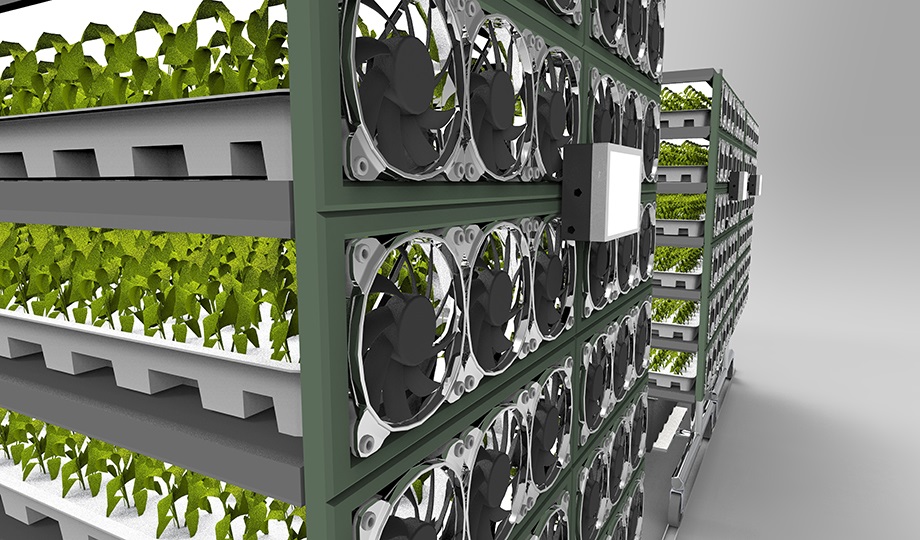

LEDs are more energy efficient and sustainable than light bulbs and fluorescent tubes, but environmental challenges are associated with them, too. One of these involves the cooling elements that prevent overheating and are usually made out of aluminium. Their manufacture and processing consumes natural resources and lots of energy.

'If we can manufacture more efficient LEDs, less electricity will be needed to generate the same amount of light; overheating would thus reduce and demand for aluminium likewise go down,' Sami Suihkonen explains.

LEDs are already common at home, but fluorescent tubes and halogen lamps still illuminate offices, stores and shops. This is due to money. When the costs of acquisition and use are added up, the difference between LEDs and fluorescent tubes, for example, is so small that switching does not make economic sense. This makes it important to also develop cheaper manufacturing methods for LEDs.

'If LED prices come down even a little, order volumes will increase, making manufacturing more efficient. Prices would then fall even more. This would establish a positive cycle, which would cut the electricity consumption of lighting,' Suihkonen envisions.

This is a big issue even on the global scale, as lighting gobbles up an estimated one-fifth of global electricity output. LEDs could help squeeze this consumption to a fraction of its present levels.

'Energy consumption has to be cut in all sectors if we want to keep living on this planet,' Filip Tuomisto points out.

The original article has been published in the Aalto University Magazine issue 12. (issuu.com).