SAN FRANCISCO – Feb. 2, 2018 – Leti, a research institute at CEA Tech, has developed a new curving technology for optical sensors and micro-displays that improves performance, enhances field of view and compensates for aberrations in optical applications.

The technology curves components such as CMOS imagers and charged-couple device (CCD) imagers for mobile phones, cameras, telescopes, medical-imaging tools and industrial-control equipment. Other uses include IR sensors for astronomy, defense, drones and micro-displays for automotive applications, augmented reality and virtual reality.

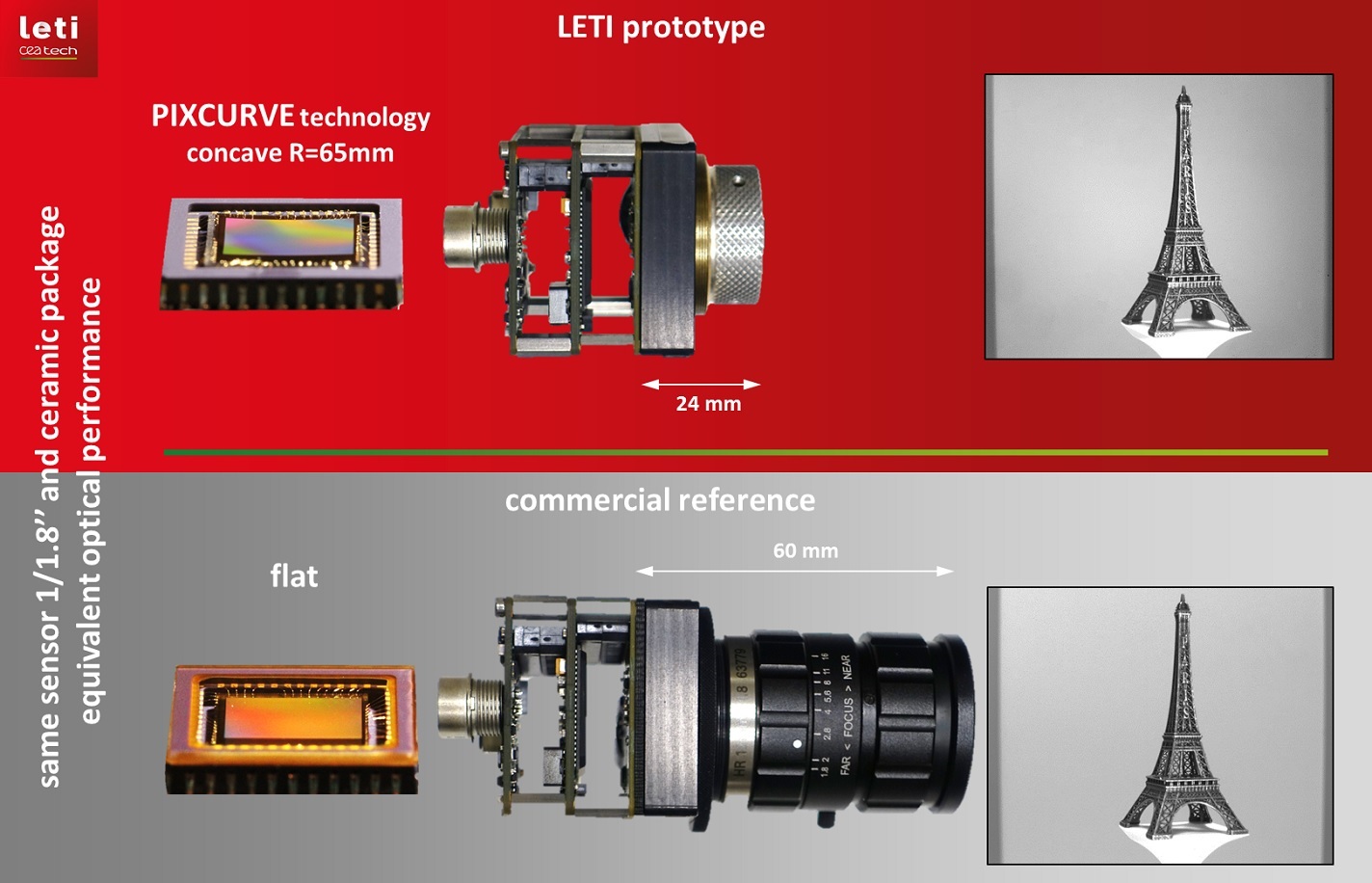

Leti's fully functional prototype of this technology was presented in the paper, "Curved Sensors for Compact High-Resolution Wide Field Designs: Prototype Demonstration and Optical Characterization", at Photonics West 2018, in collaboration with LAM (Laboratoire d'Astrophysique de Marseille). It called PIXCURVE.

"Curved sensor technology is a disruptive approach for imaging applications such as photography, videography, computer vision, surveillance and many other applications," said Bertrand Chambion, one of the paper's co-authors. "In recent years, we have seen very strong interest in curved electronics, particularly for opto-electronics systems whose performance improves, while size, complexity and cost are reduced."

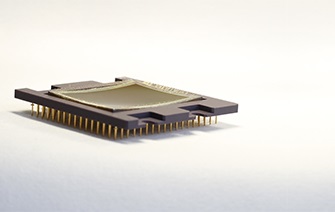

The demonstration is based on a 1/1.8'' format, 1.3-million-pixel CMOS image sensor. The standard sensor structure consists of a 7.74 x 8.12 mm silicon die glued on a ceramic package. Electrical connections are wire bonded from the die to the package surface and, then, to the interconnection board. A glass cover is placed on top for mechanical protection.

Leti's technology uses a grinding process to get the sensor below 100µm thick, which makes it mechanically flexible. It is then glued onto a curved substrate, which determines its final shape. A wire bonding process developed for electrical connections is used to prevent damages on the thinned dies. The radius of curvature is R=65mm. This prototype is compared to the equivalent commercial solution with flat sensor in Figure 1.

This process is compatible with any sensor size and with large-scale manufacturing processes.