June 12th, 2013

In the paper industry, monitoring 100% quality of thermal paper is one of the most demanding applications performed by automatic surface inspection systems. The new PAPER MASTER inspection system offered by ISRA VISION, the world's leading supplier of surface inspection systems for web products, solves this problem with flying colors. This is the reason why many leading thermal paper manufacturers around the world have issued orders to have the latest combined WIS/WBM systems with extremely fast high resolution cameras installed at their locations.

Around the globe, we are seeing an increase in the use of thermal paper, which is used, for example, in cash register roles for orders and for invoices. The NCR technology even allows the front and back page of a cash register receipt or other media to be printed at the same time, which decreases the amount of paper needed. Defects in paper manufacturing, which are often not visible to the naked eye, can lead to defects in the print order. Where Asian characters are concerned, for example, this cannot be tolerated, because even the tiniest mistake, like a missing dash, can change the meaning of the words or symbols entirely. However, even on an invoice, if a dash is missing in the number, the consequences can be fatal.

This is why highest possible print quality is so essential. That is why it is even more important that all defects are found as early as in the paper's manufacturing process, so that no complaints are reported later. Performing a 100% inspection of the web at highest speeds is a huge challenge. What's more, a high degree of processing efficiency must be ensured.

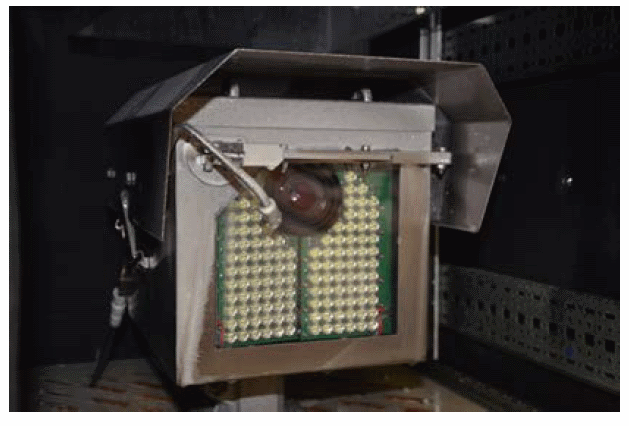

Now, there is finally a system available, the PAPER MASTER from ISRA VISION that guarantees an extremely high resolution even at high speeds. The sensor configuration is adjusted exactly to the individual requirements. The combination of low angle bright field reflection and transmission makes it possible to perfectly analyze thermal paper, for example. Because the system combines 100% web inspection and web break monitoring, an additional benefit is the increased efficiency as a result of the simple and fast process analysis. The system is designed to significantly increase production efficiency.

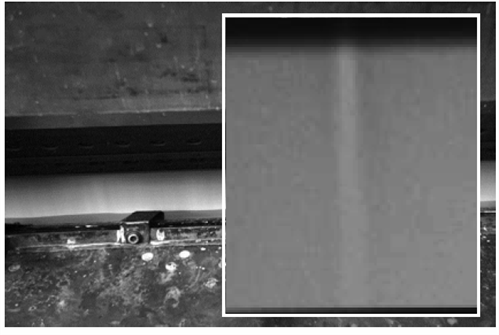

Typical streak at the curtain coater which is reliably detected by the new PAPER MASTER inspection system

Because of these sound arguments, ISRA VISION is already reporting the first major orders for the PAPER MASTER. An Asian manufacturer of thermal paper, for example, ordered several combined WBM/WIS systems. The deciding factor for this order was the new camera technology, which allows extremely high speed cameras of up to 640 mega pixels per second. The accuracy reaches 200 μm at high web speeds. This is only possible with the fastest camera and machine vision processing technology. As a special feature, separate technology for the detection of defects is being delivered directly to the curtain coater in these systems. With it, even coating defects that are invisible to the eye, such as streaks, air and dirt in coating color can be reliably identified. With this technology, the manufacturer can rest assured that even paper with Asian characters is printed correctly.

Furthermore, ISRA VISION can even report that it received orders from thermal paper manufacturers in Central and Northern Europe for combined WIS/WBM systems. For the North European manufacturer, it is of utmost importance that each and every streak defect is identified. Any streak defect can make thermal paper unusable. This is why the inspection system works at highest possible resolution in cross direction.

Inspection beam is used at the coating machine; every mm of coated paper is checked for optimum quality up to 100% in-line

Customer acceptance for the new PAPER MASTER is good. Paper manufacturers find that this system offers just what is needed for the high demands placed in the quality of thermal paper. Offering 24 hours of support 365 days a year, ISRA also ensures the highest reliable service worldwide.

For more information: