May 16, 2018

Scientists at Tokyo Institute of Technology (Tokyo Tech) and their collaborators in Swinburne University of Technology have developed a micrometer-wide thermometer that is sensitive to heat generated by optical and electron beams, and can measure small and rapid temperature changes in real time. This new device can be used to explore heat transport on the micro- and nano-scales, and in optical microscopy and synchrotron radiation experiments.

There is an urgent need for a device that can measure thermal behavior on the nanoscale and in real time, as this technology could be applied in photo-thermal cancer treatment as well as in advanced research on crystals, optical light harvesting, etc. Moreover, a miniaturized thermal microscopy system with a nanoscale heat source and detector is essential for future development of next-generation transistors that will be employed in designing new nanoscale devices.

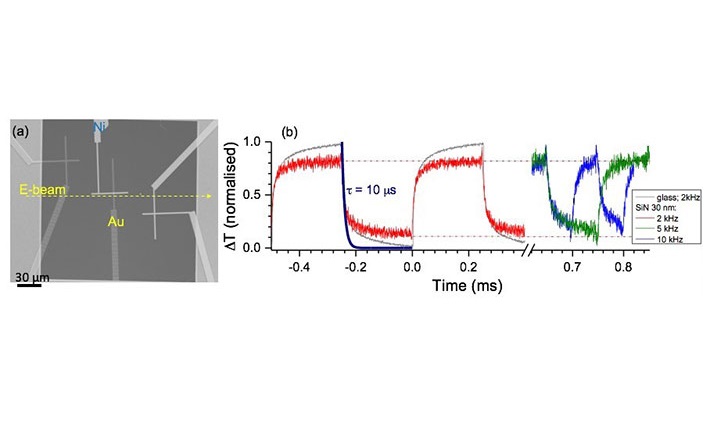

A thermocouple is an electrical device consisting of two dissimilar electrical conductors forming electrical junctions at differing temperatures. A thermocouple produces a temperature-dependent voltage, which can be interpreted to measure temperature. The micro-thermocouple recently developed by scientists at Tokyo Institute of Technology and their collaborators is of major importance to researchers in many fields. This device consists of a gold and nickel thermocouple on a silicon nitride membrane and is miniaturized to the extent that the electrodes are only 2.5 μm wide and the membrane is just 30 nm thick (Figure 1). For such a system to be used as a thermal characterization device, i.e., a thermometer, it must show sensitivity to temperature change. The developed micro-thermocouple exhibited high responsiveness to heat generated by a laser and an electron beam. Importantly, tiny temperature changes were measured by the developed thermocouple for both types of heating.

An already developed miniaturization process was used to prepare the micro-thermocouple, but critical improvements were made. In the established method, a cross pattern of metal stripes with widths of a few micrometers is created, so that a thermocouple is produced. The researchers at Tokyo Institute of Technology and their colleagues used this technique to create a pattern on a nano-thin silicon nitride membrane, which enhanced the device sensitivity and enabled it to respond faster. Through this approach, a thermometer that could measure fast and small temperature changes was successfully produced, with the measurements being performed through the nano-thin silicon nitride membrane.

As explained above, both a nanoscale heat source and a nanoscale detector are needed for a miniaturized thermal microscopy system. These requirements were successfully satisfied by the researchers, who used the nano-thin membrane and a tightly focused laser or electron beam to create a heat source with a diameter of less than 1 μm. So, combined with the micro-thermocouple detector, a nanoscale thermal microscopy system was achieved. This system can be regarded as a new "toolbox" for investigating heat transport behavior on the micro- and nano-scales, with many important applications in a wide range of fields.

Reference

Authors: Armandas Balčytis1,2, Meguya Ryu3, Saulius Juodkazis1,4 and Junko Morikawa3,*

Title of original paper: Micro-thermocouple on nano-membrane: thermometer for nanoscale measurements

Journal: Scientific Reports

DOI: 10.1038/s41598-018-24583-w

Affiliations :

1 Swinburne University of Technology, John St., Hawthorn, 3122 Vic, Australia

2 Center for Physical Sciences and Technology, Savanoriu Ave. 231, Vilnius, LT-02300, Lithuania

3 Tokyo Institute of Technology, Meguro-ku, Tokyo, 152-8550, Japan

4 Melbourne Center for Nanofabrication, Australian National Fabrication Facility, Clayton, Melbourne, 3168 Vic, Australia