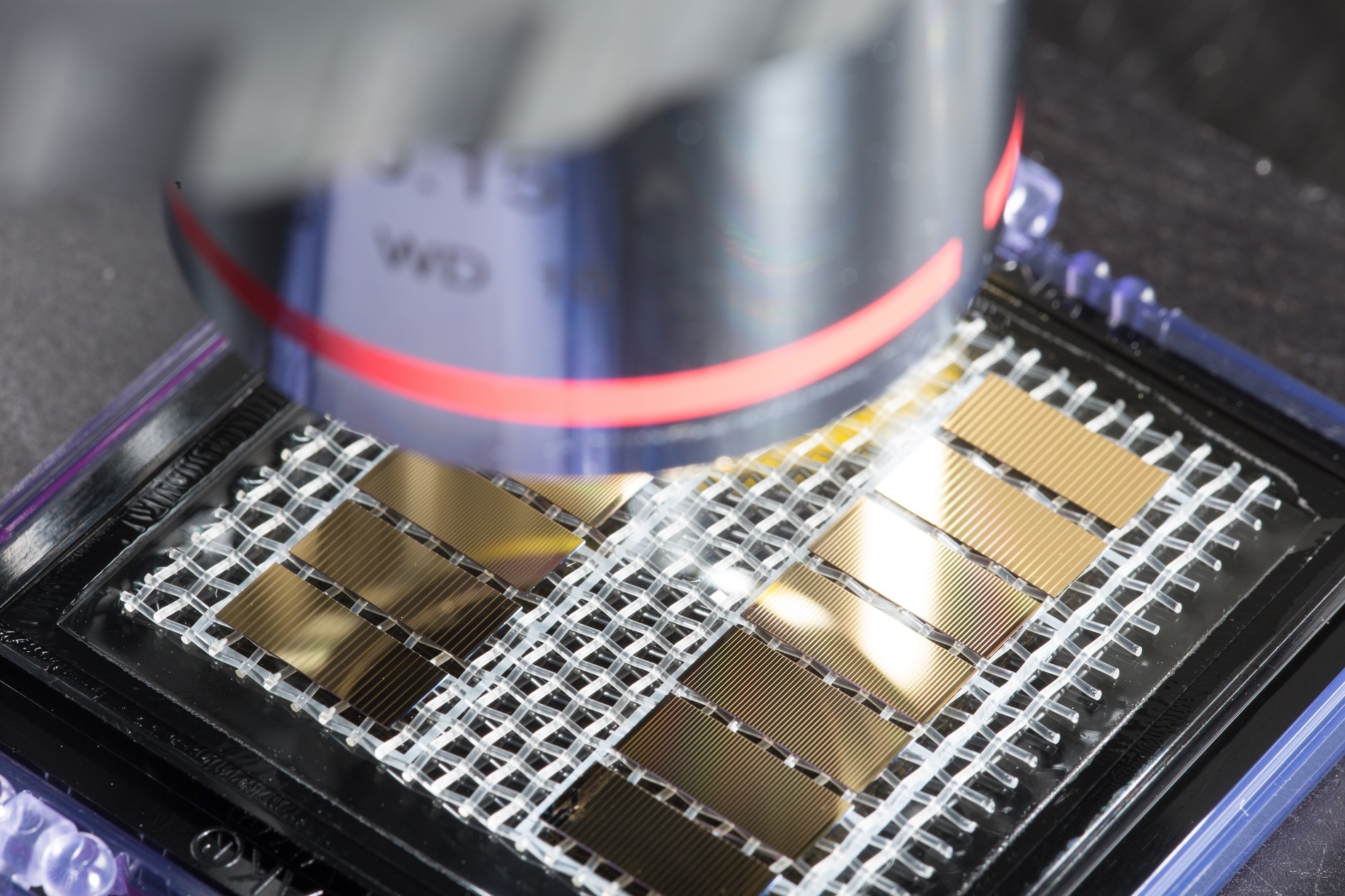

Munich / Ditzingen, June 26, 2017 – The laser and laser system manufacturer TRUMPF recently unveiled its TruDiode 4001.5 technology demonstrator at LASER World of PHOTONICS in Munich. Based on a new, patented technology known as Dense Wavelength Multiplexing (DWM), the 4 kW direct diode laser offers a brilliant beam quality of 5 mm•mrad, enabling it to be connected to a laser light cable with a core diameter of 150 µm. By way of comparison, commercially available direct diode lasers in the high-power segment typically have beam qualities of between 30 and 50 mm•mrad and are used with a 600 µm laser light cable.

TRUMPF recently unveiled the TruDiode 4001.5 technology demonstrator at LASER World of PHOTONICS in Munich.

Photo: TRUMPF

Combining power into a single beam

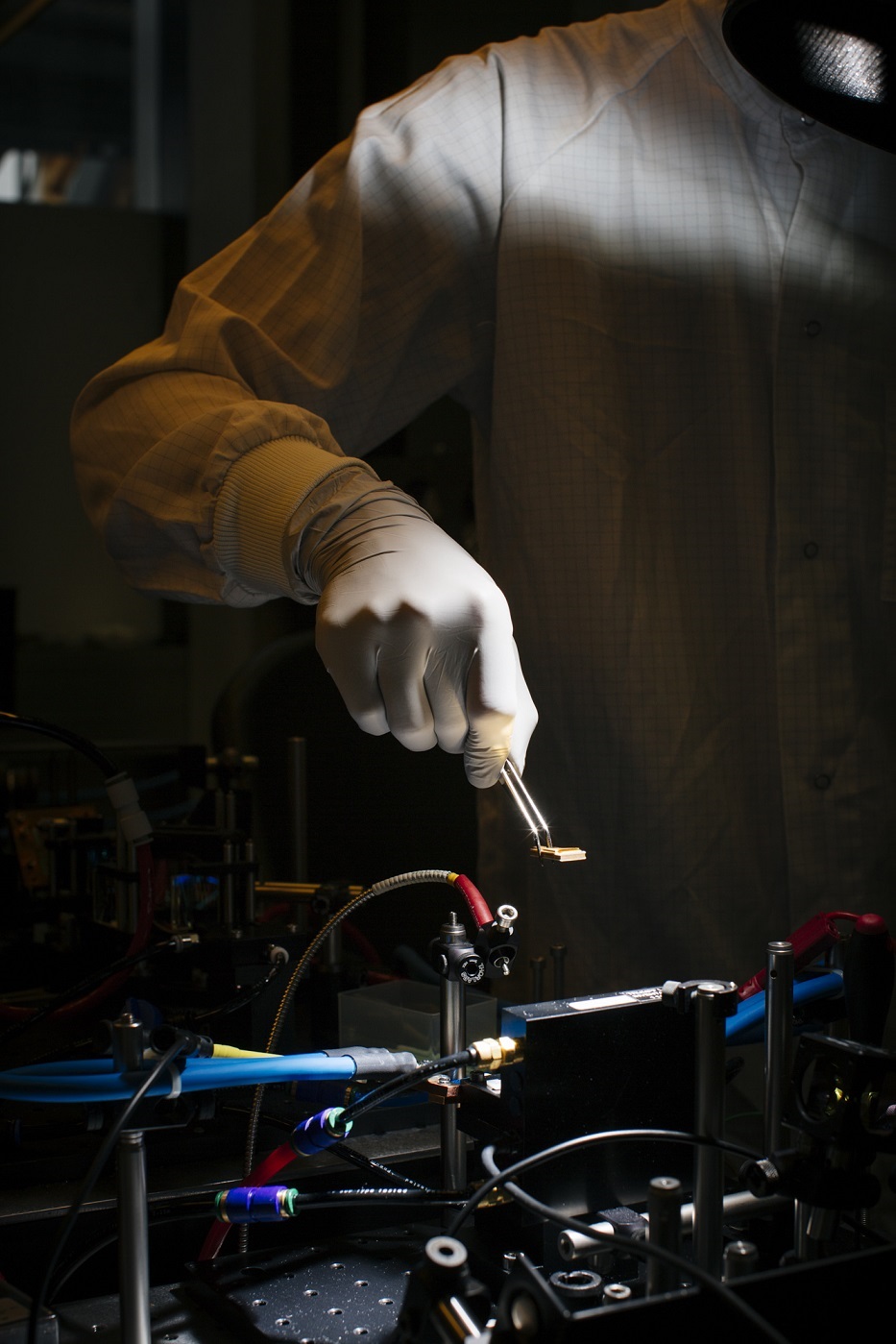

Diode lasers are based on individual diode emitters that typically have an output of just a few watts. To increase the output, multiple diode emitters are grouped into what are known as diode bars. To generate output power in the multi-kilowatt range, the current method is to spatially combine the beams from multiple diode bars and apply spectral multiplexing only to a limited extent. One of the results of this approach, however, is low beam quality. Commercially available direct diode lasers are predominantly used for soldering, heat conduction welding and surface processing, because these applications do not require high beam quality. Using the new DWM technology, a team of experts at TRUMPF has succeeded in generating a multiplexed laser beam with high beam quality by combining the outputs from individual diode emitters. “We use diodes that emit at different wavelengths. The light from the diode emitters is focused onto a diffractive optical element which combines it into a single laser beam,” says Stefanie Feuchtenbeiner, part of the TruDiode product management team at TRUMPF, describing the basic principle behind the new technology.

TRUMPF developers are determined to find the most efficient way of combining increasing output from individual semiconductor laser diodes into an ever more brilliant beam.

Photo: TRUMPF

Compact and efficient

Although the technology demonstrator showcased in Munich is a 4 kW system, TRUMPF’s initial plan is to push ahead with the development of a DWM TruDiode laser with an output of 1 or 2 kW. Offering a beam quality of 5 mm•mrad, the new direct diode lasers are suitable for both deep-penetration welding and remote welding. DWM TruDiode lasers eliminate the need for a “converting medium” such as a disk or fiber – and that makes them outstandingly compact, efficient and robust.

Much of the developers’ focus now is on making further advances in diode cooling and diode bar efficiency. Combined with the new DWM technology, this will further accelerate the evolution of the overall laser design. “The compact and efficient DWM TruDiode will be yet another key component of our ‘Power of Choice’ strategy, which is our way of making sure we offer each and every customer the best solution to meet their specific needs,” says Stefanie Feuchtenbeiner.