Feb 21, 2017

Amanda Morris

With the amazing ability to survey areas in complete darkness, night-vision cameras have revolutionized the security industry. But the materials and technology embodied in current cameras tend to degrade under temperature stress, causing night-vision devices to frequently break.

Northwestern Engineering’s Manijeh Razeghi and her team have developed a new approach to improving the technologies in night-vision cameras — potentially making these all-too-frequent breakdowns a thing of the past.

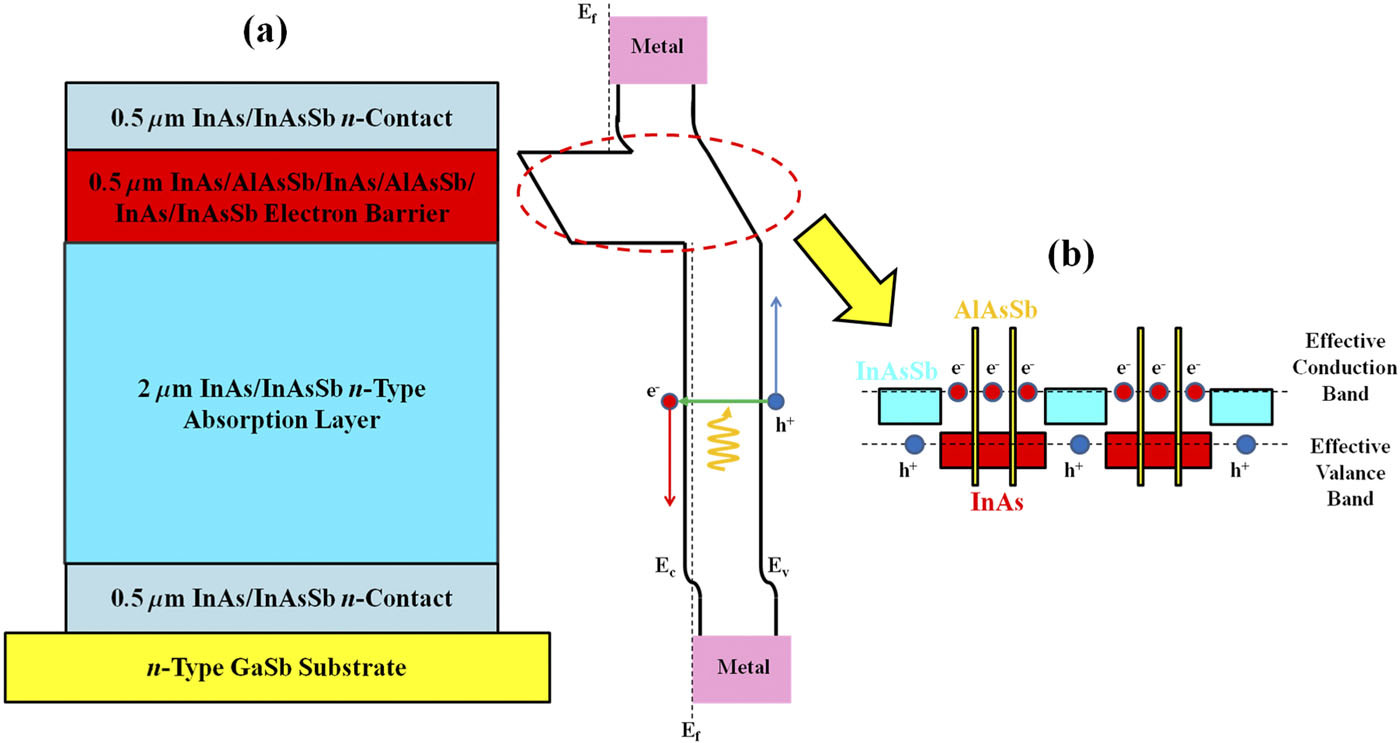

Razeghi’s team developed a breakthrough design of strained-layer indium arsenide/indium arsenide antimonide type-II superlattices, a key component for making high-performance, long-wavelength infrared photodetectors for different applications, including night-vision cameras.

“With a special superlattice-based electron barrier, the newly designed photodetector limits the obstructing dark current density, while raising the background limited infrared photodetection temperature,” said Razeghi, Walter P. Murphy Professor of Electrical Engineering and Computer Science in Northwestern’s McCormick School of Engineering. “This enables the infrared cameras to perform imaging at higher operating temperatures and reduces the need for cryogenic cooling power inside the camera.”

Supported by the Air Force Research Laboratory, Defense Advanced Research Projects Agency, and US Army, the research was published earlier this month in the journal APL Materials.

Razeghi’s new photodetector can detect the light signals from wavelengths up to 10 microns, which is the same wavelength emitted by the human body. Current state-of-the-art photodetectors are made with mercury-cadmium-telluride, for which scientists have long been looking for alternatives because it degrades under thermal stress. Mercury also poses well-known health and environmental dangers. (The international Minamata Convention of Mercury will prohibit the production and trade of products with mercury starting in 2020.)

Razeghi’s group in Northwestern’s Center for Quantum Devices is the first replace mercury with indium arsenide/indium arsenide antimonide type-II superlattices. Not only is the new replacement safer than mercury, it is also more durable. Mercury-cadmium-telluride has heat-sensitive ionic bonds that degrade under high temperatures.

Efforts to use indium arsenide/indium arsenide antimonide type-II superlattices in the past resulted in photodetectors with shorter lifetimes and inferior optical performance. But Razeghi and her team overcame this long-lasting scientific challenge by developing a “saw-tooth superlattice design,” with acted as an electron barrier to secure the material and prevent degradation.