2.6.2016

Micro-electro-mechanical systems (MEMS) are paving the way for small-sized sensor systems ready for mobile applications which allow measurements to be conducted simply on-site. Further, sensors can be easily integrated in industrial instruments in both production and processing facilities. Among others, possible applications can be found in the field of spectroscopic measurement systems, in which substances are subjected to electromagnetic or acoustic waves to detect the spectral response of the sample. Through the measurement of the unique response spectrum (“fingerprint”), solid, liquid or gaseous substances alike can be determined and analyzed. A leading international institution in the development and manufacture of MEMS, the Fraunhofer Institute for Photonic Microsystems IPMS will introduce two approaches to optical spectroscopy as well as an ultrasonic spectroscopy solution at the 2016 sensors expo taking place in San Jose from June 22-23, 2016. These technologies could be groundbreaking for the development of compact, MEMS-based, mobile mini-spectrometers.

The potential of spectroscopic measurements is enormous. The unique "fingerprint" provides detailed information about solids, liquids and gases. Because samples require no complex preparation and are not damaged by the process, measurements themselves are usually made very quickly, simply and cost-effectively. Fraunhofer IPMS scientists aim to develop ever smaller and more robust spectrometers, which are suitable for use in the field or able to be integrated in industrial measurement instruments.

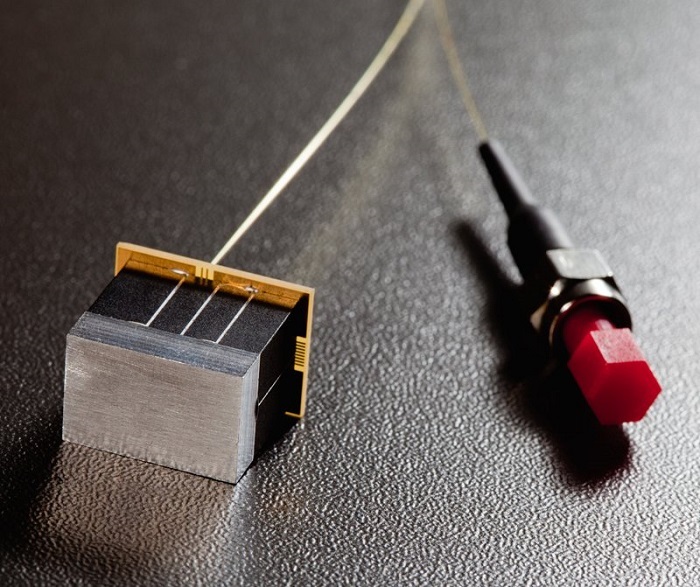

Researchers have now developed a mobile MEMS-scanning grating-spectrometer in a sugar-cube format to assist in the examination of liquid and solid substances through analyzing light in near infrared range. Able to distinguish between different powders such as sugar, sweetener or salt, the system has a volume of only 2.1 cm3, approximately 30 percent smaller than a standard sugar cube, and is controlled via an ordinary smartphone. The system enables measurements in the 950nm – 1900nm wavelength range with a spectral resolution of 10nm. Therefore, this technology is interesting for analyzing different organic compounds and a variety of applications such as portable food industry instruments, mobile medical and pharmacological analysis equipment, industrial in-situ quality testing or early warning and surveillance systems in security applications and building management.

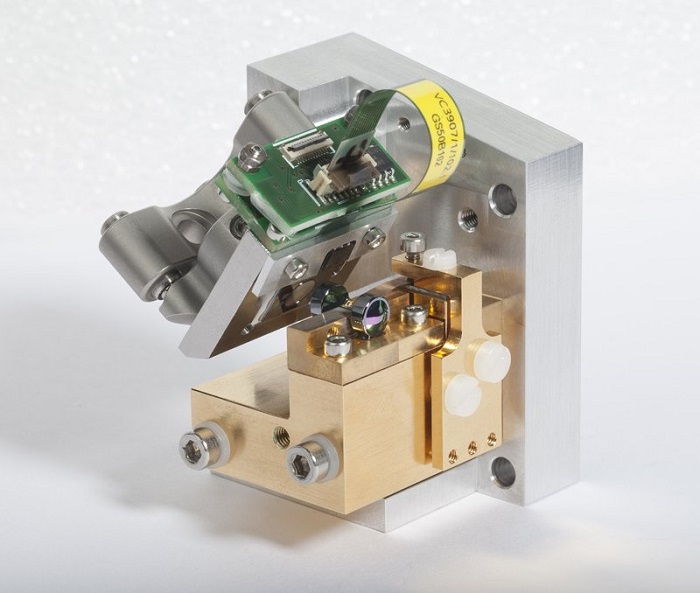

QCL module with integrated MEMS diffraction grating.

© Photo Fraunhofer IPMS

However, the characteristic absorption lines of many chemical substances important for security monitoring are not found in the near infrared but rather in the mid-infrared (3-12 microns) spectrum. In order to assess and react to potential risks such as escaping toxins over spectroscopic analysis, Fraunhofer IPMS and the Fraunhofer Institute for Applied Solid-State Physics IAF have together developed a new tunable monochromatic radiation source for the mid-infrared range. This technology provides the foundation for the development of hand-held spectrometers capable of determining the concentration of various hazardous substances quickly and on-site. At the core of the system is a combination of a quantum cascade laser in the mid-infrared spectrum developed at the Fraunhofer IAF with a MEMS scanner featuring a defraction grating with high light transmission. In order to change or tune light emitted from the quantum cascade laser, a micro-mechanically produced component with a diameter of 5mm is placed in the external resonator of the quantum cascade laser. This allows for passing through the laser wavelength with a frequency of 1000Hz and a tuning range of up to 20 percent of the central wavelength. In time division multiplexing, samples can be irradiated with different wavelengths and, by means of the “fingerprint”, the nature and concentration of contaminants can be determined.

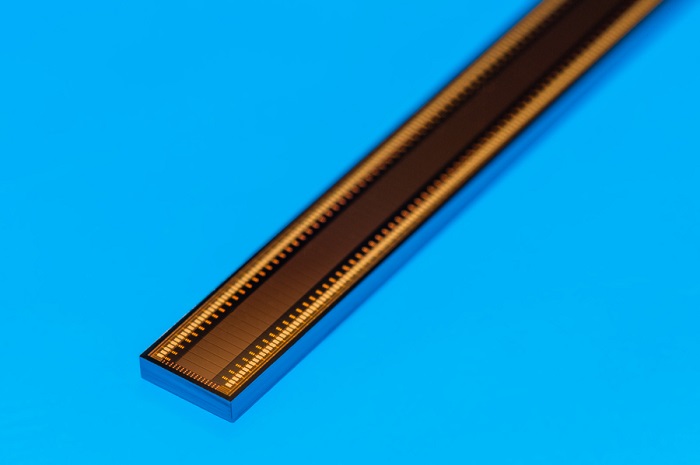

128 channel chip of a capacitive micromachined ultrasonic transducer (CMUT).

© Photo Fraunhofer IPMS

In addition to optical spectroscopy, the Fraunhofer IPMS is developing methods for acoustic spectroscopic analyses using ultrasound. These enable analyses of physical characteristics of materials as well as chemical properties of dispersions. For example, by analyzing the frequency-dependent attenuation and speed of sound, conclusions about the quality and composition of oils, alcohol-water mixtures or other fluids can be drawn. Thus, ultrasound spectroscopy is an ideal supplement to optical spectroscopy. With regard to applications in environmental monitoring, capacitive micromechanical ultrasonic transducers (CMUTs) enable the design of systems with a highly compact form factor. In contrast to conventional ultrasonic piezoelectric elements, CMUTs are manufactured by means of micromechanical manufacturing processes, yielding extremely compact devices. As sensors are integrated with CMOS circuits in a monolithic fashion, complete analysis systems can be designed on a single chip. CMUTs are ideally suited for acoustic spectroscopy as they emit sound extremely efficiently into fluids, detection is highly sensitive, and a wide frequency bandwidth can be used.

The Fraunhofer IPMS will present its research results on spectroscopy at the sensors expo in San Jose from June 22-23, 2016. The use of both optical and acoustic spectroscopy using CMUTs for the analysis of various liquid mixtures will be demonstrated. Visitors will find the exhibits at the Fraunhofer IPMS Booth 535.