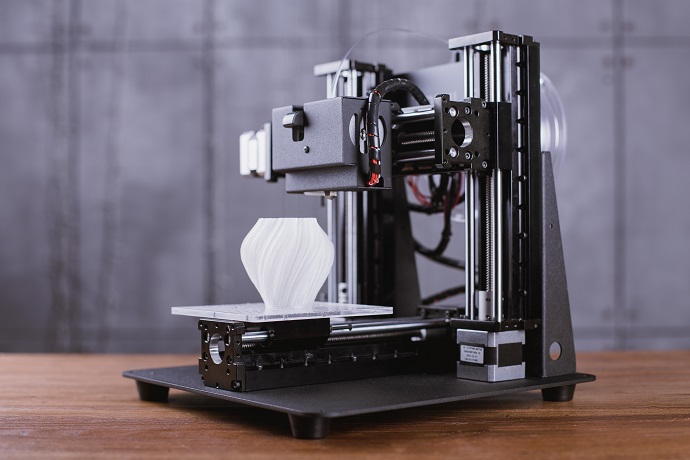

SAN FRANCISCO, California (March 30, 2016) — Trinus is the first truly affordable 3D printer for everyday professional use.

Currently, desktop 3D printers fall roughly into two camps. For under $500, users can buy a 3D printer suited for fun experimentation — one that is more toy than work machine. For $2000 or more, users can buy a printer that is suited for more serious prototyping and fabrication.

Industrial designer Bojan Smiljanic fell into this camp. As a creator of consumer products, he used to send all of his prototype designs to third-party 3D printers such as Shapeways. He did not want to spend thousands of dollars for a personal machine that might break down, fulfill only some of his needs, or require an upgrade after just a few years.

However, relying on third-party printers had its challenges too. Once, Smiljanic ordered two prints of a prototype for $100. He waited 20 days for the prototypes to arrive, only to find that they were printed with plastic that was too stiff. This type of experience was not uncommon.

Last year, Smiljanic joined Kodama, Inc., a small San Francisco-based startup looking to build a high-quality 3D printer that met the needs of professionals and hobbyists alike. They came up with Trinus, a fast, reliable, high-resolution 3D printer that can be transformed into a laser engraver within 60 seconds. Unlike most other 3D printers under $500, Trinus does not contain any cheap plastic parts — it is made entirely of premium metal.

“I wanted to make a machine that I would use as a product designer,” says Smiljanic. “With its speed,

precision, and versatility, Trinus fits the bill. The prototype printer in my office has been running 24/7

since November, with no technical failures yet.”

Trinus is available on Kickstarter until April 30 for $299.

Built to last

Constructed entirely out of high-end aluminum and steel, Trinus is the world’s only all-metal 3D printer under $500.

More than a printer

Trinus has a “transformer” design: Its 3D printing head can be taken off and exchanged with a laser engraver. By the end of 2016, we aim to launch a third head — which is why we named our product Trinus, the Latin word for “triple.” We are currently working on designs for a dual extruder (for mixing multiple filaments), a paste extruder (for printing with viscous substances such as chocolate), and a CNC router (for cutting wood and metal).

No filament restrictions

In addition to traditional PLA filament, Trinus can print with exotic materials, such as flexible, polycarbonate, wood, and aluminum filaments. Through our Kickstarter we are providing premium Polymaker filament at an exclusive discount.

Stability and precision

To make Trinus we scaled down the mechanics of industrial-grade machines. Built with a single-axis slider and robust internal components, Trinus does not require constant recalibration. Its parts stay in

place.

High print quality

Trinus maintains quality printing up to print speeds of 70 mm/sec but is capable of running at a maximum speed of 150 mm/sec. With a minimum layer height of 50 microns, its prints come out clean and smooth.

Hassle-free assembly

Since Trinus has a simple modular design and only 11 units, someone with no technical experience can

put it together in 30 minutes. Other, more expensive printers can have hundreds of pieces and require a full day to assemble.

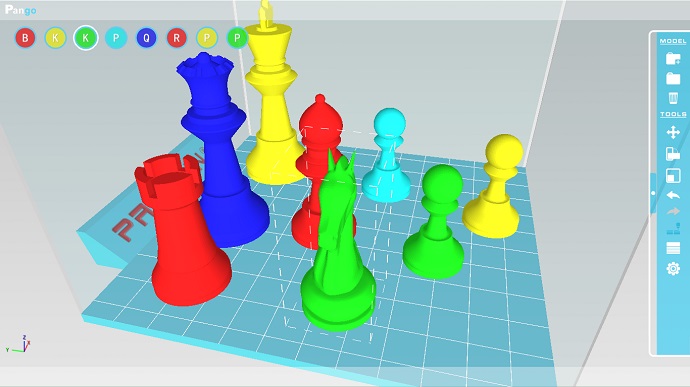

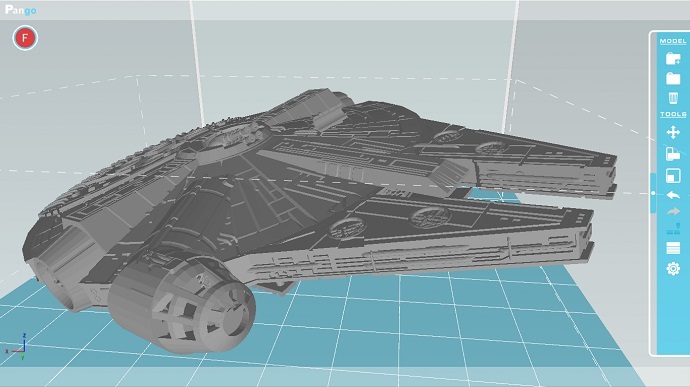

Intuitive software

Trinus comes with its own proprietary Pango software, which includes many built-in features and works twice as fast as other slicers. However, you’re not tied to Pango — Trinus is compatible with any other software package or gCode.

The Pango software

The Pango software

Tech specs

• Print volume: 120mm x 125mm x 125mm

• Print speed: up to 70 mm/sec | Moving speed: up to 150 mm/sec

• Minimum layer height: 0.05mm (50 microns)

• Print material: 1.75mm PLA, ABS, PC, flex, wood, aluminum

• OS supported: Windows, Mac

• Connectivity: USB, SD Card (autoprint)

• Power consumption: 60W

• Weight: 9.8kg

About Kodama, Inc.

Kodama is a small San Francisco-based team of entrepreneurs, designers, and engineers working on 3D printing technology. We created the Trinus 3D Printer to bring high-quality and affordable 3D printing to every creative soul.