March 1, 2016

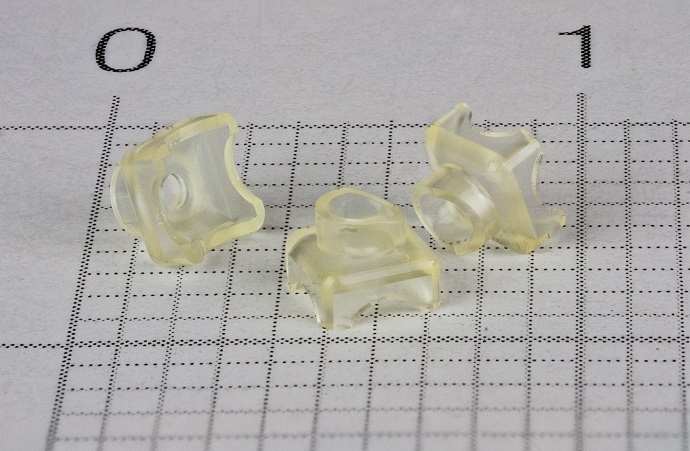

Eggenstein-Leopoldshafen: When assembling miniaturized optical systems, it is often necessary to place micro-optical elements such as single lenses or lens arrays above sensors or light-emitting devices at a specific distance.

Despite of the trend of miniaturization, most of today's standard rapid prototyping technologies do not provide the high resolution and minimum feature size that are necessary to fabricate micro-parts.

Nanoscribe’s 3D printer offers a state-of-the-art solution to product developers providing access to the highest-resolution additive manufacturing technology available today with layer thicknesses and feature sizes below 1 µm.

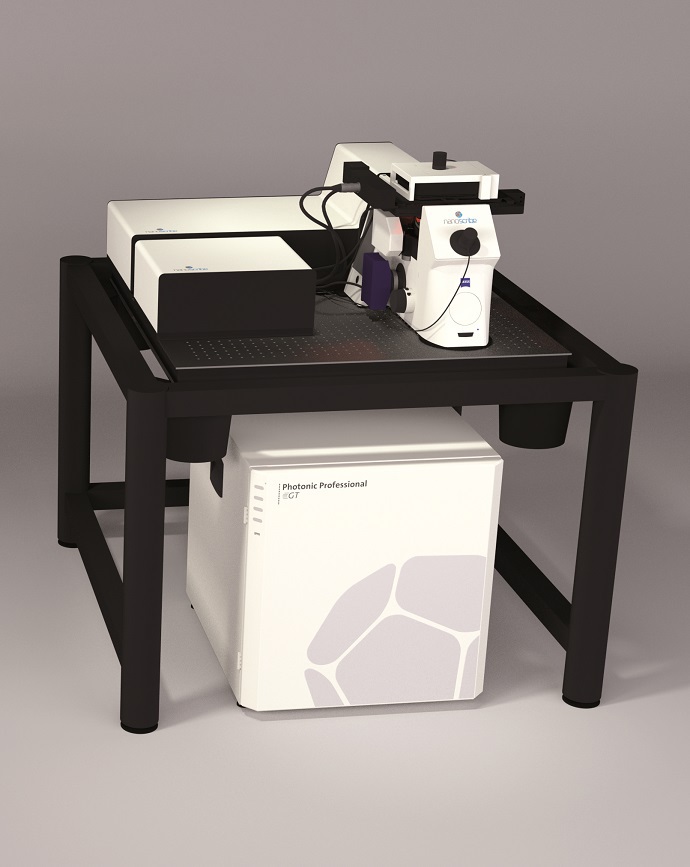

In the prototype phase within the product development process, it is often not clear a priori what the practical configuration of the micro-optical system will look like to enable optimum performance of the final product. For quick design iterations, developers therefore need rapid prototyping technologies to fabricate micro-parts, such as lens holders or mounts for miniaturized optical systems. Providing a much better resolution than micro-stereolithography, the Photonic Professional GT system - which is based on 3D laser lithography - enables design freedom and quick design iteration cycles at a scale relevant for many applications in micro system technologies, that was previously unreachable.

“Photonic Professional GT”: High-resolution 3D printer for the fabrication of structures on the micrometer and mesoscale

Technology

Nanoscribe systems base upon two-photon polymerization of photosensitive materials as the starting material. Here, the mostly liquid resist is locally solidified by a photochemically triggered polymerization. The systems use laser light in the near infrared, to which the photoresist is transparent. The laser is femtosecond pulsed, leading to extraordinary high peak powers in the laser focus. Thus, the absorption of two or more photons is triggered, causing polymerization exclusively in this focus and not along the beam path. Unexposed material is easily washed out at the end. The resolution of this true 3D rapid prototyping process goes down to less than 500 nm and delivers complex, self-supporting microstructures.

This method also allows an extremely high degree of flexibility, because the computer-controlled beam guidance can transfer 3D CAD models directly into 3D structures of almost any complexity. Furthermore this has the great advantage that production costs and component complexity are largely decoupled.

Nanoscribe

Nanoscribe GmbH is the world technology and market leader in 3D printing on the nano-, micro-, and mesoscale. Its high performance 3D printers are based on two-photon polymerization and are used in research and industry. The portfolio is complemented by tailor-made photoresists and process solutions. The performance of the groundbreaking Photonic Professional GT system was highlighted in February 2014 by the bestowal of the Prism Award in San Francisco in the “Advanced Manufacturing” category. Last year, Nanoscribe was winner of the World Technology Award (WTN) in the "Materials" category as well as one of three finalists at the “Deutscher Gründerpreis 2015” in the "Aufsteiger" category. In 2007, Nanoscribe was founded as the first spin-off to emerge from the Karlsruhe Institute of Technology (KIT).