And with the newly developed TOP Cleave optics, those materials can now be cut at a speed of one meter per second. Using this option, the new, high-performance TruMicro 5080 ultra-short pulse laser can even cut glass a millimeter thick.

Ditzingen, June 22, 2015 – Using light to machine glass. Initially, this seems like an absurd thought. The most obvious property of glass is, in fact, being transparent to light. The beams produced by a solid-state laser, usually in the infrared spectrum, thus simply pass through panes of glass. When using ultra-short pulsed laser light in the picosecond or femtosecond range, this is not the case. The massive spatial and temporal density of the photons in the pulse modify the absorption mechanism in transparent materials. This makes it possible to use laser beams to process synthetic sapphire and glass.

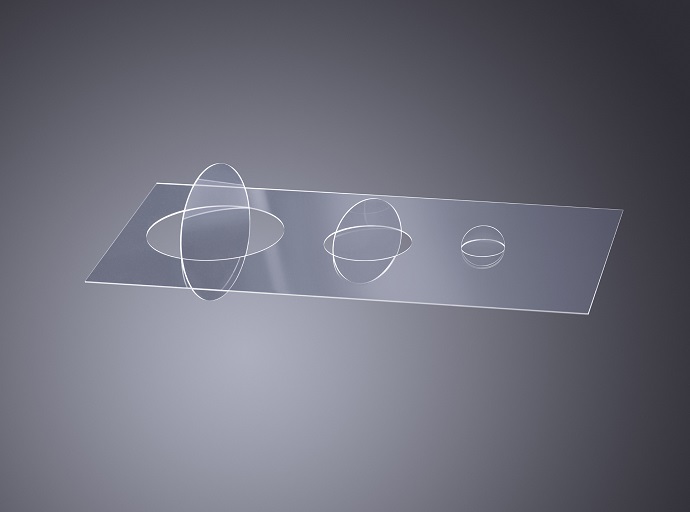

TOP Cleave optics

The TOP Cleave optics spread the power of an ultra-short pulse laser along the beam axis, creating a focus line. This increases by a hundred-fold the speed of separating glass using material modification, to one meter a second.

Photo: TRUMPF

TOP Cleave optics is the turbocharger for material modifications in glass

Instead of cutting glass by ablation, working one’s way down pulse-by-pulse, an elegant technique was recently developed to cleave thin, hardened glass such as that used in smartphone displays. Material modification is the keyword. Ultra-short pulsed laser beams are focused inside the glass and there they modify a narrow zone along the desired cleavage line. The modification generates intrinsic tensions; the glass fractures in a controlled fashion. The surface is smooth as a mirror and accurate to a hundredth of a millimeter – no matter whether straight or curved. TRUMPF will be displaying this new optics at the Laser trade fair in Munich, which can accelerate this procedure a hundred-fold: TOP Cleave. It distributes the intensity of the laser light uniformly along the axis of the beam. In this way the focus is stretched in length; the beam spot becomes a focus line. The laser pulses no longer scan the glass level by level, but instead modify – in a single pass – the complete interior separation surface. Depending on the pulse energy, this glass may be up to 700 microns thick. When working this thickness, the high-performance TruMicro lasers equipped with TOP Cleave achieve cutting speeds of up to one meter per second – a hundred times faster than without the option.

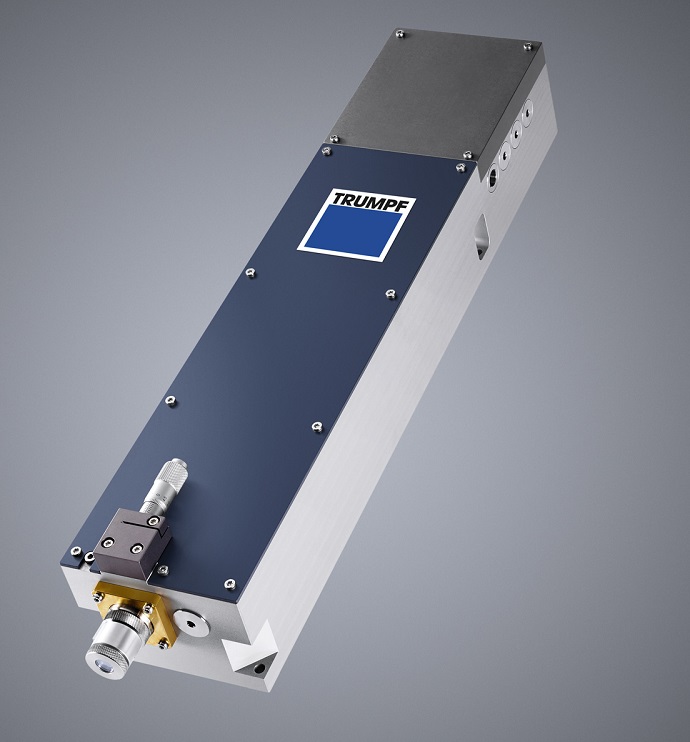

TruMicro 5080

The new flagship among the TruMicro lasers. With average power of 150 watts, repetition rate of up to 1,000 kilohertz and maximum pulse energy of 500 microjoules, this is at present the most powerful ultra-short pulse laser for industrial use.

Photo: TRUMPF

TruMicro 5080 separates glass one millimeter thick

The new flagship among the TruMicro lasers is the TruMicro 5080. It delivers, at up to 1,000 kilohertz, the highest repetition rate and with a maximum of 500 microjoules the highest-energy pulse in the world of ultra-short pulse lasers for industrial use. The laser produces average power exceeding 150 watts – making it extremely powerful in every application. The TOP Cleave optics can distribute the high power of the TruMicro 5080 along such a long focus line that the laser light can use modification techniques to separate glass more than one millimeter thick.

The TruMicro 5080 is also available in the femto edition. It is the first industrial laser that can produce femtosecond pulses in the green spectrum. In this way it joins the best of two worlds. In spite of high peak intensities, the femtosecond laser pulses inject even less thermal energy into the workpiece in comparison with a picosecond pulse. This makes them suitable especially for extremely delicate processing of metals or thermally sensitive materials like special films. Green light can be focused down to a very small spot. Green radiation has a larger Rayleigh length than infrared light and, as a consequence, greater depth of focus. This makes the TruMicro 5080 especially well suited for drilling extremely fine and precise holes such as those found in injection nozzles.

A further advantage of the TruMicro 5080 is that it can easily be integrated into industrial machinery and can be maintained while still inside the equipment. This eliminates troublesome removal and the subsequent readjustment of the beam path. A new technical concept is responsible for this. All the relevant components for maintenance and exchange – like power cables, cooling lines, the electronics and the optical area – are easily accessible from a single side. This lowers the downtime for machine tools and boosts their economy considerably. TRUMPF will also be presenting the TruMicro 5080 to the public at the Laser fair in Munich.

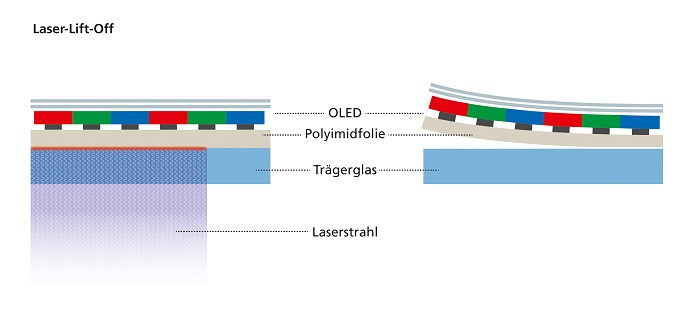

Laser lift-off

Manufacturing flexible film displays: The beam from a UV nanosecond laser is aimed from beneath, passes through the glass pane, and reaches the surface of the polyimide film. The film detaches while the sensitive OLEDs are left entirely unfazed.

Photo: TRUMPF

Laser lift-off for flexible film displays

There, visitors to the TRUMPF booth will view another application of the TruMicro lasers: The laser lift-off process for flexible films. Curved but rigid displays – and bendable panels in the future – are on the advance, particularly for the so-called “wearables” – smart devices that one wears on the body – glasses or a wristband, for example. To make up such displays the electronics industry coats backing glass panes with polyimide. The dried plastic then forms the substrate for the flexible display. Organic light-emitting diodes (OLEDs) are then applied to the polyimide. Once this has been done, the flexible display is to be released from the backing pane. To do this, a laser beam is aimed from the rear, through the backing glass, and onto the surface of the polyimide film. It heats up the film which when then loses adhesion and detaches from the backing pane. The sensitive OLEDs are completely untouched by the process.

At the fair TRUMPF will be introducing the TruMicro 7370 solid-state laser used for this process – a world premiere. When compared with the excimer laser normally employed here, the beam source requires little maintenance, increases the available operating time, and thus lowers production costs. The very short pulses make the process highly efficient, since a single pulse can work a larger surface area. The TruMicro 7370 is extremely precise in its work and highly reliable in the process. This is due to the great stability of the pulse energy and the temporal sequence of the pulses. Both are ensured by TRUMPF with a special pulse synchronization technology. The regulation installed here lends additional stability to the overall process.