July 30, 2015 — Massachusetts, USA. Acton Optics & Coatings has developed a 193nm XL high-reflectance coating that is ideal for low-fluence, high-repetition-rate excimer laser applications, particularly those associated with semiconductor R&D and test. The new coating, which boasts ≥96% reflectance (45° angle of incidence) to ≥97% reflectance (normal incidence) at 193 nm, is also an excellent choice for micromachining and materials processing applications.

The Acton 193nm XL coating is a multilayer dielectric coating that combines a hybrid structure with balanced stress optimized for excimer laser repetition rates of 4 kHz to 5 kHz. Its innovative design minimizes the possibility of catastrophic damage due to micro-defects and thermal stress fractures, as well as preventing dehydration effects from high-repetition-rate operation. This robust ultraviolet-wavelength coating passes MIL-SPEC adhesion, abrasion, and humidity tests.

Jim Diamond, business unit manager at Acton Optics & Coatings, notes, “We have been delighted to hear from our customers in the semiconductor industry that the 193nm XL coating has withstood lifetime testing that far surpasses other available coatings.”

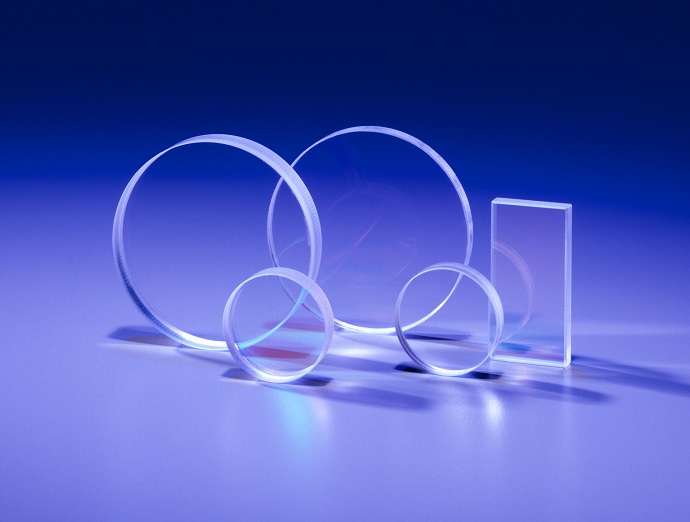

The new 193nm XL coating can be applied to Acton standard mirror blanks, custom substrates, and customer-supplied material. Reflectance and phase shift can be modified per customer request.

Alternatively, Acton Optics & Coatings offers a 193nm mirror coating optimized for high-fluence, low-repetition-rate (~200 Hz) excimer laser applications. This special “e” design takes electrical field intensity (EFI) correction to the next level by positioning and distributing EFI peaks within several layers, thus reducing the intensity within any single layer in the stack. Subsequently, the effect of EFI-related damage is diminished, resulting in increased laser-damage resistance and longer coating lifetimes.