December 15, 2014

Two new prototypes for tiny chip-based thermometers are illuminating light’s potential to revolutionize the way temperature is gauged. With further development, these photonic thermometers are expected to perform as well as or better than the traditional platinum resistance thermometers (PRTs), with the additional advantages of being smaller, more robust, resistant to electromagnetic interference, and potentially self-calibrating, say the researchers from PML’s Sensor Science Division who are producing this work.

Photonic thermometers could even become the new standard for thermometry someday. And because these micrometer-scale prototypes are built into chips, they could be produced in bulk and integrated into existing systems.

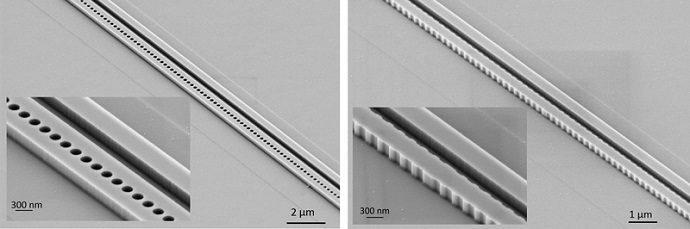

One of the team’s new sensors consists of a silicon waveguide etched with a single Bragg grating, a kind of filter for light that reflects certain wavelengths and allows others to pass. Temperature determines which frequencies of light are reflected by the grating.

In the range (from 5 °C-160 °C) that they have studied with this device so far, researchers observed a temperature response about 8 times better than that of Bragg gratings etched into more fragile fiber optic cables. And the relative simplicity of their design, which can be written to a chip in one pass, means thermometers using this technique could be relatively inexpensive and easy to manufacture.

In a second prototype, the Bragg filter is replaced with a photonic crystal, which consists of a silicon waveguide less than a millionth of a meter wide bored through with holes that scatter incoming light like miniature mirrors. Preliminary tests in the range of approximately 20 °C-40 °C have shown that the photonic crystal thermometer is sensitive to temperature change, with a clear shift in the peak frequency of about 70 picometers (a trillionth of a meter) per degree C.

Both the photonic crystal and the newest version of the Bragg grating device, which employ cavities that enhance the signal, are expected to achieve accuracies of at least a tenth of a degree Celsius. Eventually their range of operation should stretch from -269 °C to the melting point of silicon at more than 1000 °C.

SEM images of a photonic crystal cavity thermometer (left) and waveguide Bragg grating cavity thermometer (right). The inserts show a closer view of the central section — the signal-enhancing cavity — for each thermometer.

As proofs of principal, the works open up a wide domain of thermometry applications for both photonic crystal and silicon-based Bragg grating sensors, including being buried into walls or sent into space. The designs could also be adapted for humidity and pressure measurements and even – in the case of the photonic crystal device – chemical trace analysis.