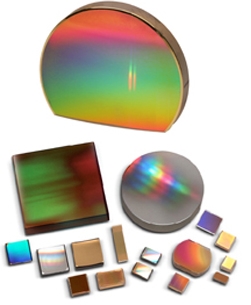

Fitchburg, Massachusetts, July 17, 2013 -Headwall Photonics, Inc. is responding to increased demand from original equipment manufacturers (OEMs) for high-performance small-form-factor diffraction gratings used in their precision optical instruments.

Application areas include color management, plant phenotyping, pathogen detection, semiconductor fabrication, process monitoring, and remote sensing. Although end users need instruments having exceptionally high signal-to-noise (SNR), high spatial and spectral resolution, and low stray light, they also want simplified optical designs that lower size, weight, and cost. Aberration-corrected holographic diffraction gratings deliver these performance characteristics and are also temperature insensitive for suitability in applications that range from ground to space.

Original gratings, unlike those produced using replication techniques, are guaranteed to meet groove profile and density specifications from prototype to production. Headwall's gratings are aberration-corrected, meaning that unwanted optical effects such as keystone and smile are eliminated. Headwall's cost-effective, high-volume manufacturing process for all-original gratings means that OEMs can move from prototype to production rapidly.

"We are seeing a fundamental shift toward small form-factor spectral instruments across all the markets we serve," stated Headwall CEO David Bannon. "Our OEM customers can differentiate their instruments thanks to the unmatched optical precision and efficiency of our aberration-corrected holographic gratings." These instruments can be found not only in laboratory settings, but in airborne platforms and satellites as well. "Temperature insensitivity is a crucial differentiator for our diffractive optics technology," noted Bannon. "Customers want to make sure that the high optical performance that they demand is locked in no matter where or how their instrument is used." Headwall's gratings can routinely survive temperatures exceeding 80 degrees C (to 150 degrees C upon request).

Headwall's gratings are used in UV, VIS, NIR, IR, absorption spectroscopy, fluorescence spectroscopy, hyperspectral and Raman spectroscopy, CARS spectroscopy, and more. Designs can be fiber-matched and self-referencing if needed and are simplified by Headwall to reduce size, complexity, and cost.

About Headwall Photonics

Headwall Photonics is a leading designer and manufacturer of hyperspectral imaging spectrometers and spectral instrumentation for industrial, commercial, and government markets.

Headwall's high performance Hyperspec family instruments have been selected by military/defense departments, OEMs, and end-user customers around the world for use in critical application environments. The Hyperspec Starter Kit is a fully integrated hyperspectral system that includes a hyperspectral sensor, all necessary control software, illumination, and moving stage.

Headwall enjoys a market leadership position through the design and manufacture of spectral instrumentation that is customized for application-specific performance.

For information www.headwallphotonics.com