Ditzingen, 12 November 2013 – This year TRUMPF is expanding its line of short and ultrashort pulse lasers intended for processing micromaterials by introducing six new beam sources operating in the picosecond range. Two of these beam sources will be seen in live applications at the 2013 Productronica.

Brilliant debut in cold machining

The new TruMicro Series 2000 offers an affordable and appealing entry into microscopic machining. Lasers with pulse duration of just 20 picoseconds deliver ten microjoules of pulse energy and average output power of ten watts, at high brilliance. With an M² beam quality of less than 1.3, these are suitable for high-precision separation and structuring. Thus the TruMicro Series 2000 is able to ablate thin film layers made of polyimides or other plastics – as little as 100 nanometers thick. Controls also monitor each individual picosecond pulse, from pulse generation through to pulse delivery, by way of the external modulator. As a result, output power and pulse energy are kept exactly at the required levels, regardless of any external influences. The interplay of the individual control units is patented and is known at TRUMPF as the double feedback loop. These small and lightweight lasers are also distinguished by their compactness and their many and varied control options, making it simple to integrate them into manufacturing lines. Variations with infrared or green wavelengths give the user a choice in regard to focusing ability and the required absorption properties. The TruMicro 2220 will be showing its qualities as it cuts thin polyamide films at the trade fair booth. These films, thanks to their flexible structures, are used in the circuitry for portable devices like smartphones and tablet PCs.

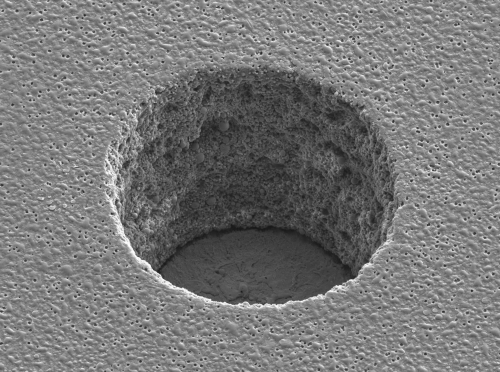

Printed circuit boards

The TruMicro Series 5000 can punch up to one thousand holes – as small as 30 microns in diameter – per second. There will be no swelling at the edge of the hole. This image was made with a reflection electron microscope.

New performance record, making for high productivity

In the TruMicro Series 5000, TRUMPF is expanding its product portfolio in the direction of higher average performance. This is to achieve optimum productivity and profitability in industrial manufacturing. The new TruMicro 5080 at IR wavelength stretches the power envelope among picosecond lasers to more than 150 watts of average output power. Once again, it achieves a record among industrial ultrashort pulse lasers. The frequency-doubled version – the new TruMicro 5280 operating in the green spectrum – also breaks the 100-watt barrier in terms of average output power. This higher performance is achieved by the two ultrashort pulse lasers with beam quality typical of TruMicro, where M² is less than 1.3. The lasers offer pulses less than ten picoseconds in duration.

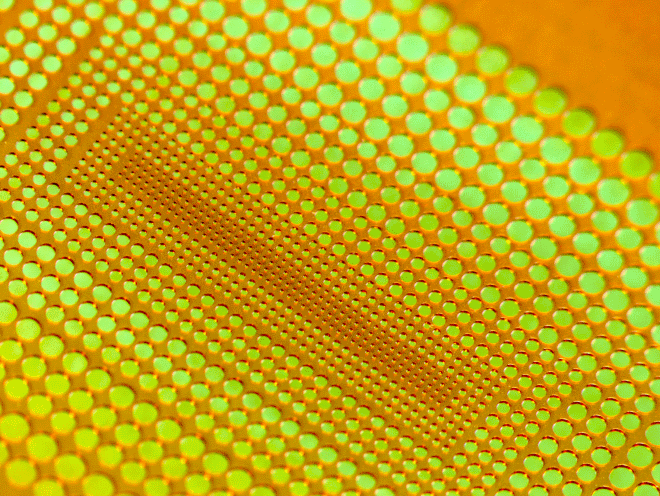

Polyimide film

Creating holes in a plastic printed circuit film, using TRUMPF picosecond lasers.

These properties predestine the TruMicro 5080 and 5280 for demanding operations in manufacturing semiconductors and electronics. The newest applications include drilling and cutting sensitive materials such as ceramics, sapphire and silicon carbide, as well as drilling holes in printed circuit boards. Here the ultrashort pulse lasers in the TruMicro Series 5000 make full use of their strengths. Using cold processing, they avoid stress-induced microfissures in hard, brittle components in spite of the high production tempo, with a repetition rate of up to 800 kilohertz. When manufacturing circuit boards comprising up to 40 layers, these units achieve the required velocity, creating as many as one thousand 30-micron holes per second. These holes, lined with copper, join the conductor tracks over several levels. This requires maximum precision in terms of power, pulse energy and beam quality. The patented double feedback loop makes possible this exactness in regulation.

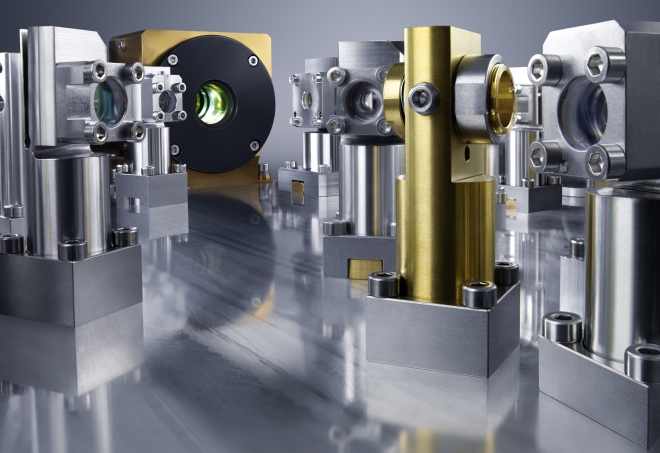

TruMicro 2000

The new picosecond lasers in the TruMicro Series 2000 make it possible to process microscopic materials using low average power outputs.

Long-life UV lasers for materials sensitive to temperatures

Celebrating their world premiere in Munich are the ultraviolet picosecond lasers – the TruMicro 5350 and TruMicro 5360. With service lives exceeding 10,000 hours, they are in the market’s premier league, measured according to UV laser availability in industrial use. TRUMPF has managed to do this without having to use a “micro mover” to shift the crystal. In this way, any sudden variations in beam location and quality are excluded from the very outset. Also outstanding is the average output power of 15 watts during pulses less than ten picoseconds long. The pulse energy, at up to 50 microjoules, is also exceptional. This results in the highest peak pulse power available – at the 343-nanometer wavelength – for industrial purposes. In regard to beam quality, the UV system is equal to the infrared and green versions, with M² of less than 1.3. This wavelength makes focusing even more precise. Specimens containing holes just ten microns in diameter exhibit an extremely narrow zone of thermal influence and no swelling at the edge. The TruMicro 5350 and 5360 models are excellently suited for low-k grooving when manufacturing computer chips. Low-k dielectrics make possible high clock rates in microprocessors, since they prevent the appearance of parasitic capacities. In addition, they protect the delicate tracks on the wafers. These materials will, however, interfere with the procedure for dicing the wafers to form individual chips. The TRUMPF UV lasers remove this layer both quickly and precisely; the wafer can then be cut without interference. Their excellent focus and the wavelengths available also make the TruMicro 5350 and 5360 the ideal tools for working temperature-sensitive materials such as high-performance thermoplastics, polymers and PET.